Pharmaceutical and Biotech

Pharmaceutical and Biotech

JM Canty

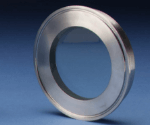

Site Glasses, Tank Lights (LED)

Particle Size Analyzers

Level Detectors

BioCam Visual Cameras

Foam Detectors

Cell Viability Analyzers

Schneider Electric

Mass Spectrometry Analyzers for Fermenters and Bioreactors with 2-second response

Process Instrumentation (Pressure, Flow, Level, Temperature)

Wireless Instrumentation

Liquid Analytical (pH, Conductivity)

Valves and Positioners

Draeger Safety

Gas Leak Detectors for Ethylene Oxide

Hydrogen Peroxide

Oxygen, and LEL, Gas Leak and Flame Detection Systems

Portable Gas Detectors for Confined Space

Eaton MTL

Intrinsic Safety Barriers, Isolators, Lights, Horns, and Marshalling Systems

Hazardous Area Displays and Visualization

Hazardous Area Power Supplies, Surge Protectors for Panels and Equipment

Foundation Fieldbus Power Supplies and Distribution Hardware

HART Multiplexing and Distribution

EXPO Purge Technologies

Purging and Pressurization Systems for Enclosures and Motors, Room Pressurization Systems

Hazardous Area Label Printers

Eurotherm

Validated Environmental Storage Data Recording

21 CFR 11 Data Recording with Audit Trail

Precision Temperature Control

EcoStruxure Maintenance Advisor