Hazardous Area Electrical Protection

NEAL SYSTEMS TOP PRODUCTS AND SOLUTIONS FOR HAZARDOUS AREA ELECTRICAL PROTECTION

MTL

Expo Technologies

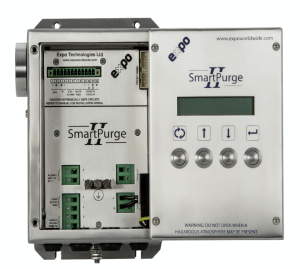

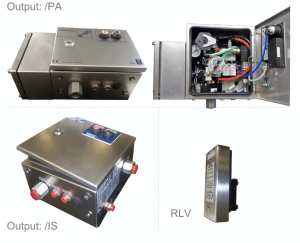

SmartPurge II

SmartPurge II

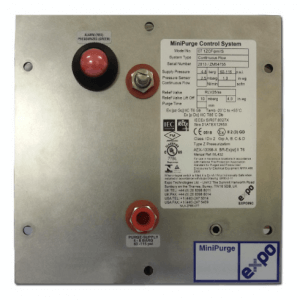

MiniPurge Type X – Leakage Compensation

MiniPurge Type X – Leakage Compensation

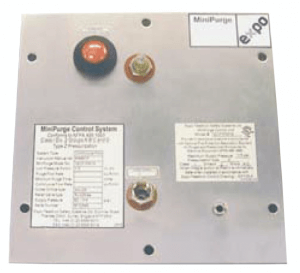

MiniPurge Type X – Dust Protection

MiniPurge Type X – Dust Protection

MiniPurge Type Z(Y) – Continuous Flow

MiniPurge Type Z(Y) – Continuous Flow