Vibration Monitoring of Water, Wastewater and Stormwater Treatment Plants

June 5, 2024 | Product NewsThis article describes how the rotating machinery at a Water Treatment Plant, Wastewater Treatment Plant and Stormwater Management System should be monitored to enable proactive maintenance, reduce downtime, increase equipment lifespan, and improve operational efficiency by identifying potential issues before they escalate into major problems. It outlines how vibration monitoring can help you take a proactive approach to maintain the operational efficiency, safety, and environmental integrity of water, wastewater and stormwater treatment facilities. It allows for early detection of equipment issues, optimized processes, and overall, more sustainable, and reliable plant operations.

Why is vibration monitoring of water, wastewater and stormwater plants needed?

Vibration monitoring is crucial in water, wastewater and stormwater plants for several reasons. These plants house equipment and machinery that are essential for the treatment and processing of water, wastewater and stormwater. Monitoring vibration helps ensure the smooth and efficient operation of these facilities, as well as the safety of personnel and the environment. Here are some key reasons why vibration monitoring is essential:

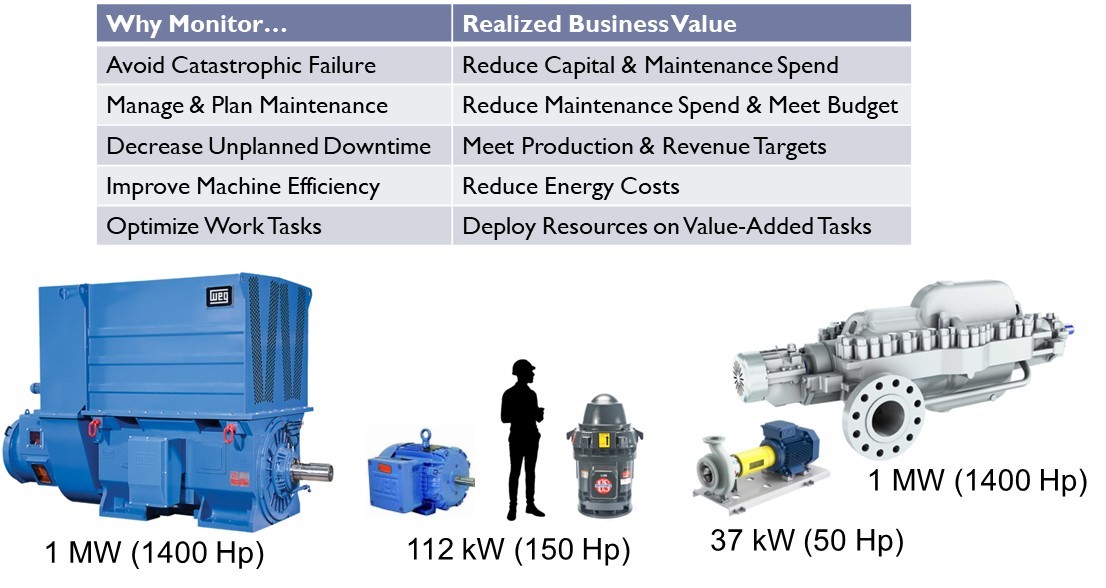

Equipment Health and Condition Monitoring: Water and wastewater plants, and stormwater facilities typically rely on a variety of rotating machinery, such as pumps, motors, blowers, and mixers. Continuous vibration monitoring allows operators and maintenance personnel to assess the health of these machines. Unusual levels of vibration can indicate wear and tear, misalignment, unbalance, or other issues that might lead to equipment failure. Detecting problems early enables proactive maintenance and reduces the risk of costly breakdowns.

Figure – Why Vibration Monitoring

Early Fault Detection: Monitoring vibrations helps identify potential faults or malfunctions before they cause severe damage to the equipment. Early detection allows for timely repairs or replacements, minimizing downtime and avoiding more extensive and expensive repairs.

Energy Efficiency: Unwanted vibrations in equipment can result in energy inefficiencies. Monitoring vibration levels enables operators to optimize equipment performance, reducing energy consumption and operating costs.

Process Optimization: The efficiency of the treatment processes can be affected by vibration-related issues. Monitoring vibrations can help identify process inefficiencies caused by equipment problems, allowing for adjustments and improvements to maintain optimal treatment performance.

Environmental Protection: These treatment plants play a vital role in protecting the environment. Vibration monitoring helps prevent potential environmental hazards by identifying equipment problems that could lead to leaks, spills, or other incidents that might harm the surrounding environment.

Personnel Safety: Excessive vibrations in equipment can pose safety risks to plant personnel. Vibrations can lead to equipment failure, which might result in accidents and injuries. By monitoring and addressing vibration-related issues promptly, the safety of plant workers can be significantly improved.

Regulatory Compliance: Industrial treatment plants often need to adhere to strict regulations and guidelines. Vibration monitoring may be a requirement in some regulatory frameworks to ensure the proper functioning and maintenance of critical equipment.

Asset Management and Longevity: Monitoring vibrations provides valuable data for asset management. Understanding the condition of equipment helps in planning maintenance schedules and replacement cycles, extending the life of the machinery and avoiding unplanned downtime.

How is vibration monitoring used in these industries?

Vibration monitoring plays a crucial role in the water, wastewater and stormwater industries by helping to ensure the reliable and efficient operation of equipment and infrastructure. Here are some ways in which vibration monitoring is used in these industries:

Pump and Motor Monitoring: Pumps and motors are extensively used in water, wastewater and stormwater treatment plants. Vibration monitoring helps in detecting abnormalities in the rotating equipment, such as misalignment, bearing wear, unbalance, and mechanical looseness. By monitoring vibration levels, plant operators can identify potential failures and schedule maintenance proactively, minimizing downtime and reducing repair costs.

Pipe and Valve Monitoring: Vibration monitoring is employed to detect pipe and valve failures in treatment systems. Excessive vibration can indicate issues like water hammer, fluid flow problems, or structural weaknesses in the piping network. Continuous monitoring allows for early detection of leaks, pipe bursts, or valve malfunctions, enabling prompt repairs and preventing water loss or environmental contamination.

Blower and Compressor Monitoring: Blowers and compressors are vital components in aeration systems used in wastewater treatment. Vibration monitoring helps to identify issues such as worn bearings, unbalance, and alignment problems in these machines. By detecting these problems early on, maintenance can be scheduled to avoid costly breakdowns and optimize energy efficiency.

Mixing and Agitation Equipment: In various treatment processes, mixing and agitation equipment are used to ensure proper blending of chemicals and facilitate solid-liquid separation. Vibration monitoring assists in identifying problems like impeller damage, bearing wear, or mechanical faults in mixers and agitators. Timely maintenance based on vibration data helps to prevent equipment failure and optimize process performance.

Structural Monitoring: Water, wastewater and stormwater treatment infrastructure often includes large structures like reservoirs, tanks, and dams. Vibration monitoring is employed to assess the structural integrity of these assets. By monitoring vibration levels and frequencies, engineers can detect any abnormal vibrations that may indicate structural damage, settling, or excessive loads. This information helps in evaluating the safety of the structures and planning necessary repairs or reinforcements.

What are the challenges in vibration monitoring of these industrial treatment plants?

While vibration monitoring offers numerous benefits in water, wastewater and stormwater plants, there are also several challenges that need to be addressed. Here are some common challenges associated with vibration monitoring in these industries:

Harsh Environment: These treatment plants often have harsh and corrosive environments, with high humidity, chemical exposure, and elevated temperatures. These conditions can affect the performance and lifespan of vibration monitoring equipment, such as sensors and data acquisition systems. Specialized vibration monitoring equipment with robust construction and suitable materials is required to withstand these environments.

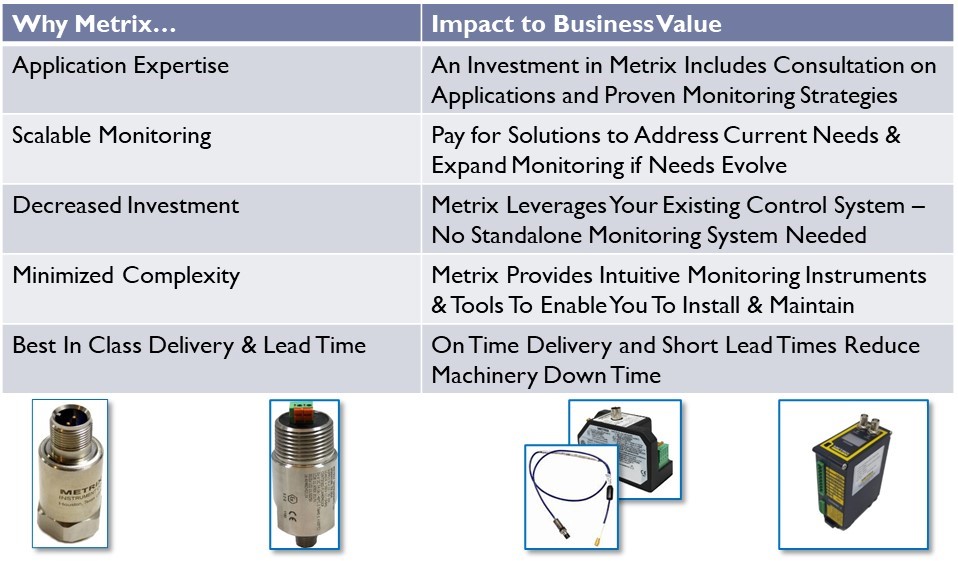

Sensor and or Transmitter Placement: Proper sensor placement is crucial for effective vibration monitoring. However, in such treatment plants, it can be challenging to identify the optimal locations for vibration transducers due to limited accessibility, crowded equipment layouts, and complex piping networks. It may require careful planning and consideration of factors such as vibration transmission paths, potential sources of vibration, and critical equipment locations. Metrix can be relied upon to help with proper vibration transducer placement.

Data Interpretation: Vibration monitoring generates a significant amount of data, and interpreting this data correctly can be challenging, that is why people have relied upon Metrix Vibration for their simple 4-20 milliamp output for trending purposes for decades. This simple tool allows plant operators to easily see changes in vibration levels. After early warning is provided plant operators and maintenance personnel can focus on the machines that need attention. This allows experts that have a good understanding of vibration analysis techniques and interpretation methods to identify problems and avoid impending failures. Training and expertise in vibration analysis are useful for effective decision-making based on the collected data.

Integration with Maintenance Strategies: Vibration monitoring should be integrated into a comprehensive maintenance strategy to be effective. The challenge lies in establishing an effective system that connects the vibration monitoring data with maintenance planning and scheduling. This integration involves setting up thresholds and alarms, establishing protocols for action based on vibration data, and ensuring timely follow-up on identified issues to prevent failures or breakdowns.

Cost Considerations: Implementing a vibration monitoring program requires an investment in equipment, software, and training. Small and medium-sized plants with limited budgets may face challenges in allocating resources for vibration monitoring. Cost-effective solutions and prioritization of critical equipment are important considerations to overcome this challenge. Metrix provides solutions that are economical, easy to install and that are modular to fit within any budget.

Addressing these challenges requires a combination of appropriate technology, expertise, and effective implementation strategies. By overcoming these obstacles, these treatment plants can optimize their maintenance practices, improve equipment reliability, and ensure the efficient operation of their facilities.

What solutions do we advocate for vibration monitoring of water, wastewater and stormwater plants?

Some general solutions that are commonly advocated for vibration monitoring of such industrial treatment plants are noted below. These solutions can help optimize the vibration monitoring process:

Robust Vibration Sensors and Transmitters: High-quality vibration sensors and transmitters specifically designed for harsh environments are crucial for accurate and reliable monitoring. These sensors are capable of withstanding the corrosive and demanding conditions found in such plants. They are adequate protection against moisture, chemicals, and temperature variations.

Wireless Monitoring Systems: For Balance of Plant rotating machines, implementing wireless vibration monitoring systems can simplify installation and reduce the complexity of cable routing in treatment plants. Wireless systems enable flexible transducer placement and provide data transmission to central monitoring stations. This allows for easier access to vibration data, efficient data management, and timely analysis.

Advanced Signal Processing and Analysis: Vibration monitoring systems should incorporate advanced signal processing algorithms and analysis techniques to filter out background noise and extract meaningful information. These techniques help in accurately identifying vibration patterns, detecting anomalies, and providing early warning indications of potential equipment failures.

Remote Monitoring and Analytics: Cloud-based or remote monitoring platforms allow plant operators and maintenance personnel to access vibration data and analysis remotely. This provides the convenience of real-time monitoring, data visualization, and trend analysis from any location. It facilitates proactive decision-making, immediate response to critical alerts, and comprehensive data-driven maintenance strategies.

Integration with Maintenance Management Systems: Integrating vibration monitoring systems with existing maintenance management systems or computerized maintenance management systems (CMMS) streamlines the workflow and enhances maintenance planning. By connecting vibration data with work order generation, scheduling, and asset management, it ensures seamless coordination between vibration analysis results and maintenance activities.

Expert Support and Training: Vibration monitoring in water, wastewater and stormwater treatment plants can benefit from expert support and training. Metrix offers technical assistance, training programs, and consultation services to help plant personnel understand the vibration monitoring process, interpret data accurately, and make informed maintenance decisions.

Conclusion

Overall, vibration monitoring in the water, wastewater and stormwater industries enables proactive maintenance, reduces downtime, increases equipment lifespan, and improves operational efficiency by identifying potential issues before they escalate into major failures.

It’s advisable to consult with vibration monitoring solution providers, such as Metrix Vibration or other reputable companies in the industry, to understand their specific offerings and how they align with the unique requirements of your industrial treatment plant.

In conclusion, vibration monitoring is a proactive approach to maintain the operational efficiency, safety, and environmental integrity of water, wastewater and stormwater treatment plants. It allows for early detection of equipment issues, optimized processes, and overall, more sustainable, and reliable plant operations.

Figure – Why Metrix for Vibration Monitoring

Contact Neal Systems here to request more information on how Metrix can suit your needs.