< Company News

Fast Communication and Configuration for the Heat Treatment of Metals

October 11, 2023 | Company News

Neal Systems’ newest team members Jordan Baum and Justin Bendik are excited to be able to provide the amazing product line of Canty to their oil & gas, metals, pharmaceutical, chemical, food & beverage customers.

JM Canty decided to extend NSI’s coverage to include the Western Pennsylvania and West Virginia territories.

If you have industrial process tanks, Canty provides four main ways to help visualize your application:

If you’ve got a process tank or furnace application that needs enhanced visualization for your operators to help improve quality control – JM Canty has a solution to help!

If you use Draeger Fixed or Portable Gas Leak Detectors at your facility in eastern PA, Delaware, New Jersey, and NYC Metro, Neal Systems is your local Draeger-authorized service provider for all repairs and calibration work that you might need to be done. Neal Systems had to go through extensive training and ensure proper hardware/software compliance in order to be authorized to help keep your facility safe with your Draeger products.

In addition, Neal Systems can often advise any upgrading that you might want to consider for older Draeger devices or units from other manufacturers. In many cases, newer units have advanced diagnostic, communication, and longevity upgrades that are extremely beneficial.

Let us know if you need any calibration work done on your plant’s gas leak detection equipment!

If your water, wastewater, or storm water runoff facility had a critical pump that went down for just ONE day unexpectedly, how would that impact your bottom line? Neal Systems, along with our partners from Metrix Vibration and Alta Solutions, have 20 years of experience providing custom vibration/temperature monitoring systems for many different types of pumping systems.

A properly designed rotary machinery monitoring system on a large pump can often spot critical problems such as worn bearings, shaft misalignment, pump cavitation, or other defects before they become severe.

Our experts utilize knowledge from design standards such as the Hydraulic Institute to ensure that you have an effective understanding of baseline values, normal operating values, as well as alarm scenarios. This data can be used to either perform shut-down operations, or alert a local operator, a local SCADA / DCS or PLC, and even trended for long-term evaluation.

How healthy are YOUR pumps?

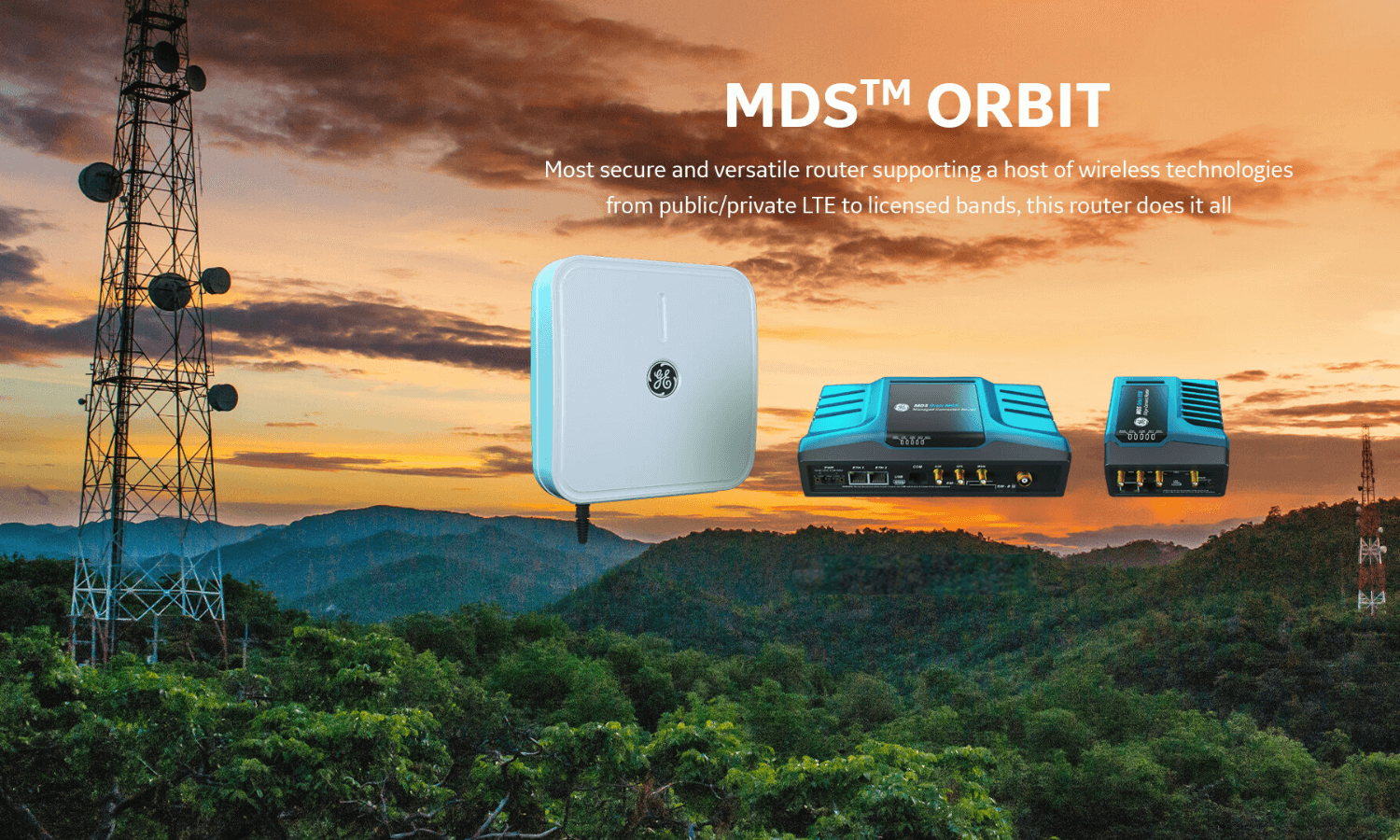

For 20+ years, Neal Systems has been helping companies navigate the challenges of industrial wireless solutions, with our specialties being licensed/unlicensed spread spectrum as well as cellular modem solutions.

Thanks to extensive training from MDS platform by GE Vernova, we can now add a new unique platform combining both of those capabilities – the GE MDS Orbit MCR (Multiservice-Connect Router). This wireless radio provides an industry-unique advantage of dual radio uplinks which help minimize network downtime with capabilities such as signal-quality-based smart auto-failover and other redundancy features. In addition, customer hybrid communications networks are supported with popular use cases such as licensed narrowband and LTE connectivity in one solution.

In addition, the MDS Orbit offers secure industrial-grade public and private LTE in various spectrums, including the following options:

Neal Systems recently received training on deploying this unique platform for any company that needs an industrial wireless solution with additional redundancy failover – with an extensive engineering team of MDS engineers standing behind us to help make sure you get an industrial wireless solution with maximized uptime that you can trust.