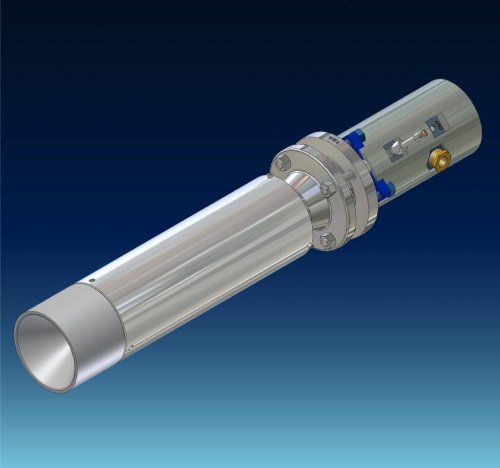

Unlocking Precise Dew Point Measurement with the Portable XPDM Dew Point Meter

October 30, 2023 | Product News

In various industries, the need for quick and accurate dew point measurements is undeniable. Whether you’re involved in natural gas processing, the petrochemical industry, HVAC systems, power generation, pharmaceuticals, or food processing, having a reliable instrument for spot-checking moisture in gases and liquids is crucial. That’s where the COSA XENTAUR™ Portable XPDM™ Dew Point Meter steps in, providing a portable and easy-to-use solution for accurate dew point measurements.

The Portable XPDM Dew Point Meter is a versatile tool with a wide range of applications. Here are some of the key industries that benefit from its capabilities:

Natural Gas Processing: Measure moisture content in natural gas pipelines, storage tanks, and processing facilities to ensure safety and efficiency in the natural gas system.

Petrochemical Industry: Use the XPDM to measure moisture content in various gases and liquids, including propane, butane, and other hydrocarbons.

HVAC Systems: Measure moisture content in HVAC systems to optimize performance and prevent issues caused by excess moisture, such as mold growth.

Power Generation: Ensure the efficiency and safety of power generation processes by measuring moisture content in steam and other gases in power plants.

Pharmaceutical Industry: Maintain the quality and stability of drugs and other products by measuring moisture content in the pharmaceutical industry.

Food Processing: Ensure the quality and safety of various food products by measuring their moisture content.

Features

The Portable XPDM Dew Point Meter comes packed with a range of features to meet your moisture measurement needs:

High Accuracy: Provides highly accurate dew point temperature measurements with an impressive accuracy of up to ±0.2°C.

Wide Measuring Range: Measures dew point temperatures from as low as -110°C to as high as 20°C, suitable for a wide array of applications.

Fast Response Time: Offers real-time measurements with a response time of less than 5 minutes, allowing for swift assessments.

User-Friendly: Designed for ease of use with a clear and intuitive display and simple one-button operation.

Portable: Its lightweight and compact design make it easy to carry and use in the field.

Versatile: Capable of measuring the moisture content of various gases and liquids, including natural gas, compressed air, hydrogen, nitrogen, and more.

Data Logging: Store up to 10,000 measurement data points, which can be easily downloaded and analyzed later using the included software.

Durability: Built to withstand harsh industrial environments and boasts a long battery life.

Spancheck™ – Ensuring Calibration in the Field

One unique feature of the Portable XPDM Dew Point Meter is the Spancheck™ function, which plays a crucial role in maintaining the instrument’s accuracy over time. Spancheck allows users to check the calibration of the instrument right in the field, which offers several benefits:

Ensures Accuracy: Quickly and easily check the accuracy of the instrument on-site, ensuring reliable measurements without additional equipment or specialized skills.

Saves Time and Money: Eliminates the need to send the instrument for periodic calibration checks, reducing downtime and saving costs.

Increases Productivity: Verify the calibration on-site, enhancing productivity and efficiency in your operations.

Reduces Risk: Reduces the risk of inaccurate measurements, which can lead to costly errors or safety hazards in various applications.

Benefits

The Portable XPDM Dew Point Meter comes with a range of benefits, including:

HTF™ Sensor Technology: Ensures extremely fast response times.

Portable Measurements: Easy-to-carry and use in various applications.

Sensor Technology: Reliable and accurate measurements.

Single Point Calibration: Simplifies the calibration process.

Six Different Engineering Units: Offers flexibility in measurement.

Spancheck™ in the Field: Ensures ongoing accuracy.

Special Long-Life Battery: Provides up to 100 hours of continuous monitoring.

Carrying Case Available: An optional accessory for added convenience.

Applications

The versatility of the Portable XPDM Dew Point Meter extends to various applications, including:

- Cryogenic Gas Producers

- Custody Transfer

- Electrical Insulating Gases

- Feedstock Gases

- Gas Cylinders and Air Separation Plants

- Instrument Air

- Natural Gas Pipelines

- Petrochemical

- SF6 Moisture Measurements

- Shipboard LNG and Aviation Oxygen

- Specialty Gas Producers

The COSA XENTAUR™ Portable XPDM™ Dew Point Meter is a game-changer for industries that require accurate dew point measurements. With its high accuracy, wide measuring range, fast response time, and user-friendly design, it’s a reliable tool for on-site moisture content assessment. Additionally, the Spancheck™ feature ensures ongoing calibration accuracy in the field, saving time and money. In a wide range of applications, this portable dew point meter proves to be an indispensable asset for optimizing processes, ensuring safety, and maintaining product quality.