Cement Industry Conveying and Feeding Equipment Must-Haves

February 10, 2026 | Product NewsWeighing and feeding equipment is critical in the cement industry to provide accuracy, process stability, product quality, and energy efficiency. The cement industry requires robust, specialized conveying and feeding equipment to handle a variety of bulk materials, including abrasive materials ranging from limestone to fine powders. The equipment must provide continuous and precise flow of materials and operate in extremely harsh and strenuous operating conditions.

Cement manufacturers rely on rugged and durable conveying and feeding equipment in each step of the process. They must accurately track and measure inbound raw materials (e.g., gypsum, clinker, silica and limestone) and closely monitor in-process material consumption. In addition, precise ingredient blending and accurate final-product dispatch is also critical to product quality and operational efficiency.

Conveying Equipment

Robust conveying equipment is essential, it is used to transport materials between different stages of the production process, and the distances can be far. Belt conveyors are the most common and versatile conveyors used for long-distance and high-capacity transport and continuous and precise feeding of bulk materials such as limestone, clay and clinker. These heavy-duty conveyors can be run horizontally or on an incline and utilize robust belts and components that are heat-resistant, durable and designed to withstand harsh environments. These Conveyors also often incorporate Belt Scales to continuously measure the mass flow of the bulk materials and these must also be extremely durable while able to consistently and accurately provide critical process data.

Bucket Elevators are used for vertical transport to lift materials like raw meal, clinker and finished cement from a lower point in the production process to a higher one. They are compact and have a tall lifting range to move material, such as feeding material into a grinding mill or storage silo.

Pneumatic Conveying Systems use air pressure (or vacuum) to move powdered materials (like finished cement) through sealed pipelines over long distances. They offer excellent material containment, preventing dust emissions and their pipelines can be routed around obstructions but these systems do require additional equipment including blowers and air filters.

For short-to-medium distances, Screw Conveyors can be used to transport fine, powder-like materials, such as fly ash, cement, and dust. They have a rotating screw inside a trough or tube and are ideal for controlled volumetric feeding and dust containment.

Feeding Equipment

Feeding equipment is required to extract material from storage (hoppers or silos) and to deliver it continuously and uniformly into process machines such as crushers, mills, or kilns at a precise, controlled rate.

Vibratory Loss-in-Weight Feeders are suitable for feeding bulk materials, such as coarse limestone, before they enter a crusher. Vibration is used to move and regulate the flow of the material, including irregular shapes, larger particles, pellets, and powders.

Table Feeders are used to extract and feed smaller, granular or powdery non-sticky materials from silos or hoppers with an adjustable flow rate, often for blending purposes.

More robust heavy-duty apron feeders that use metal plates (aprons) linked by chains serve to extract and feed very large, heavy and highly abrasive raw materials, such as run-of-mine ore from hoppers, especially for primary crushing applications.

Rotary Feeders can be used control the discharge rate of fine, powdered material from storage and act as an airlock in pneumatic conveying applications and to minimize cold air leakage into high-temperature systems like the raw mill inlet.

Weigh Belt Feeders

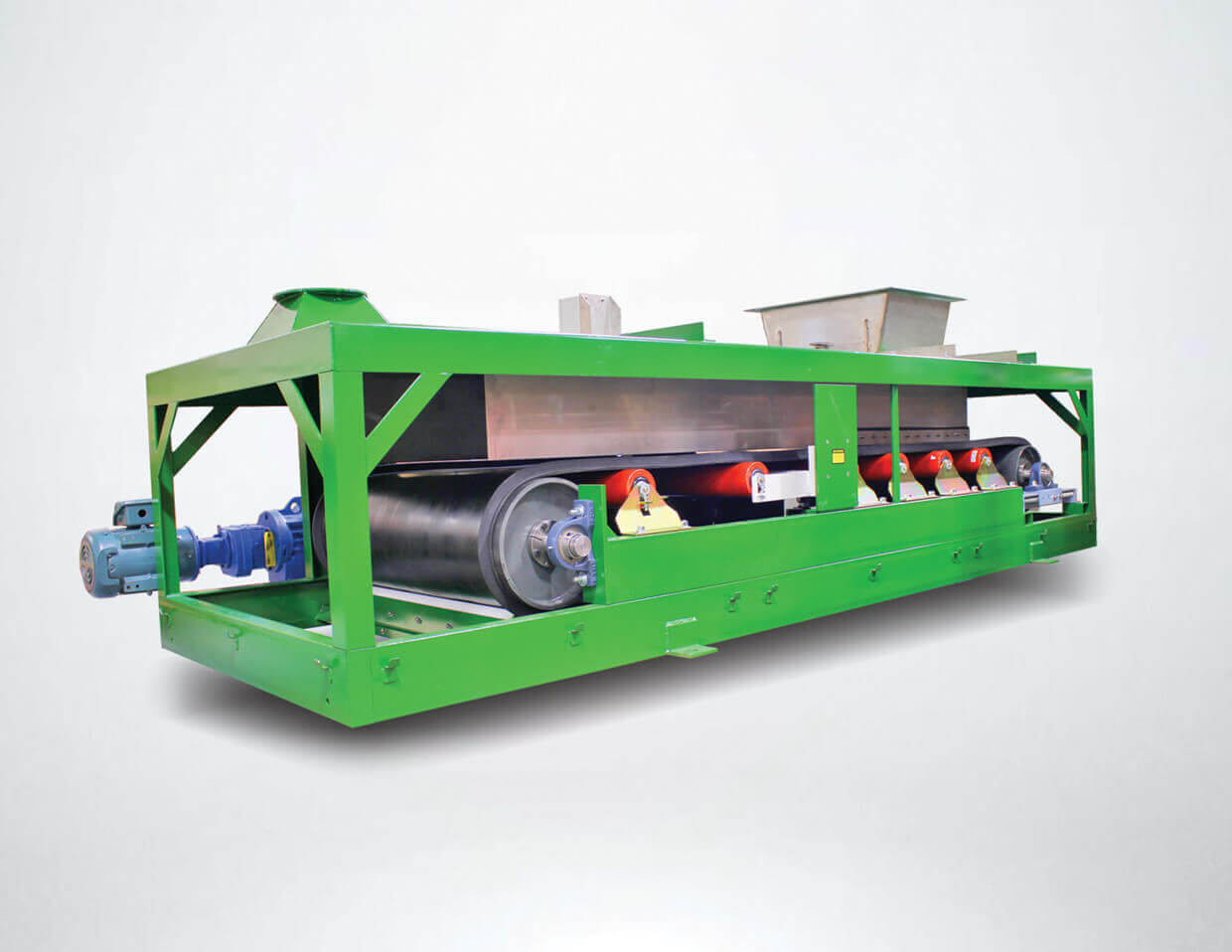

Weigh Belt Feeders (or Weigh Feeders) are ideal for a range of controlled feeding and accurate material proportioning applications. These are short, self-contained, belt conveyors that incorporate an integral belt scale and can be used to continuously monitor and control the material mass flow rate before it enters key processes (raw mill or kiln). These are critical for quality control and blend optimization. They provide high precision, are excellent for a wide range of feed rates and suitable for blended cement production.

Originally developed in the 1970s for the cement industry, Thayer Scale’s Model MD & MDL feeders are extremely rugged weigh belt feeders commonly used across many heavy industrial applications. These Weigh Belt Feeders are proven to withstand extreme environmental conditions, including abrasive dusts, corrosive fumes, wide temperature fluctuations and vibrations – without any detrimental effects to performance or accuracy. With the Model MD being able to handle flow rates between 2 – 400 STPH and the MDL being specifically designed for the lower end of that range, both styles of feeder offer a range of rugged weigh belt options ideally suited for harsh industrial environments.

The Model MD and MDL are suitable for heavy, compacted, high bulk density materials of all particle sizes. They are the ideal feeders for medium to high feed rates for both general and heavy industrial applications.

Built to Survive

Recently, Neal Systems sold a replacement Weigh Belt Feeder to replace a unit originally installed in 2008 in a harsh outdoor cement production environment. Being “Built to Survive” this equipment had been running well for nearly twenty years, providing accurate rate measurement. After many years of reliable service, the frame of the feeder was beginning to succumb to corrosion under the harsh operating conditions. The replacement unit was upgraded to a full stainless-steel frame construction, which will result in an even longer service life

The Weigh Belt Feeder, a Model MD-24-TM, is used to meter iron ore into the production process. Iron ore is added to cement to enhance its strength and accelerate the hydration process. As a fluxing agent, iron ore helps chemical reactions with calcium and aluminum during high-temperature processing, forming compounds like tricalcium aluminoferrite, which contributes to the hardness and strength of the cement.

This manufacturer uses several other Weigh Belt Feeders and Conveyor Belt Scales in their cement product process to handle materials like limestone, gypsum, clinker, petroleum, coke, slag, fly ash, all used to create a variety of construction materials.

In addition to the cement industry weighing and feeding equipment is used throughout a wide range of industries and bulk material handling applications and it is essential to have the correct equipment in place to ensure the accurate and precise flow control of material at every stage of your process.