January 13, 2021 | Company News

If your facility utilizes large rotary machinery such as pumps, compressors, fans, blowers, or turbine/generator sets, this presentation is for you!

John Lamp, Neal Systems Technical Lead, will be presenting at the Engineers Joint Committee of Long Island’s Engineers Week Webinar Series on good vibration practices and modern technologies that can help monitor and alarm on significant vibration events and trends. The goals of this presentation are to teach a basic understanding of the fundamental concepts behind vibration monitoring and provide exposure to examples of modern technological solutions available in the industrial market, including wireless vibration sensors, with a focus on the strengths and weaknesses of different types of technology.

This course will count for 2 PDH credits.

A variety of courses are being offered. See the full schedule and how to sign-up here!

January 5, 2021 | Company News

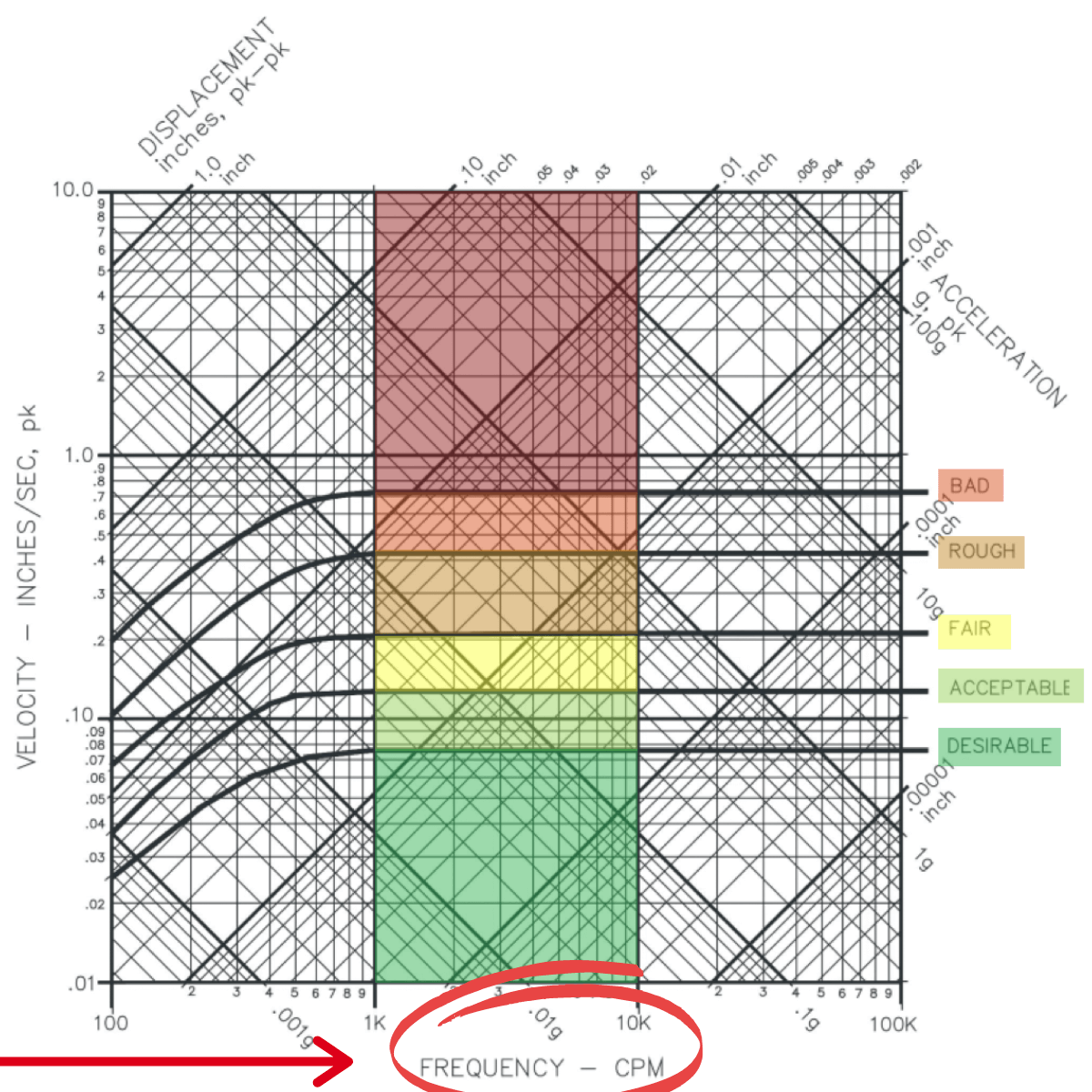

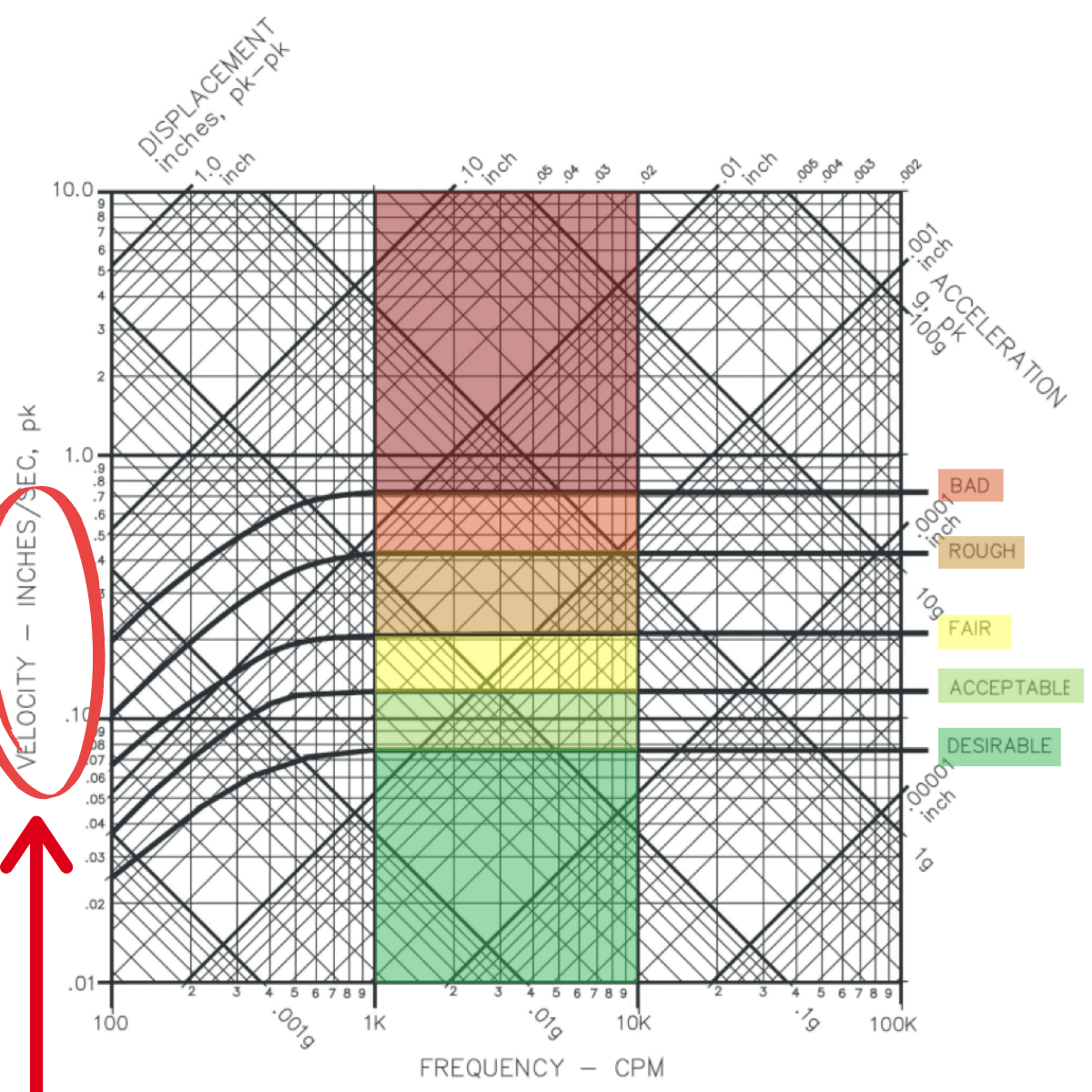

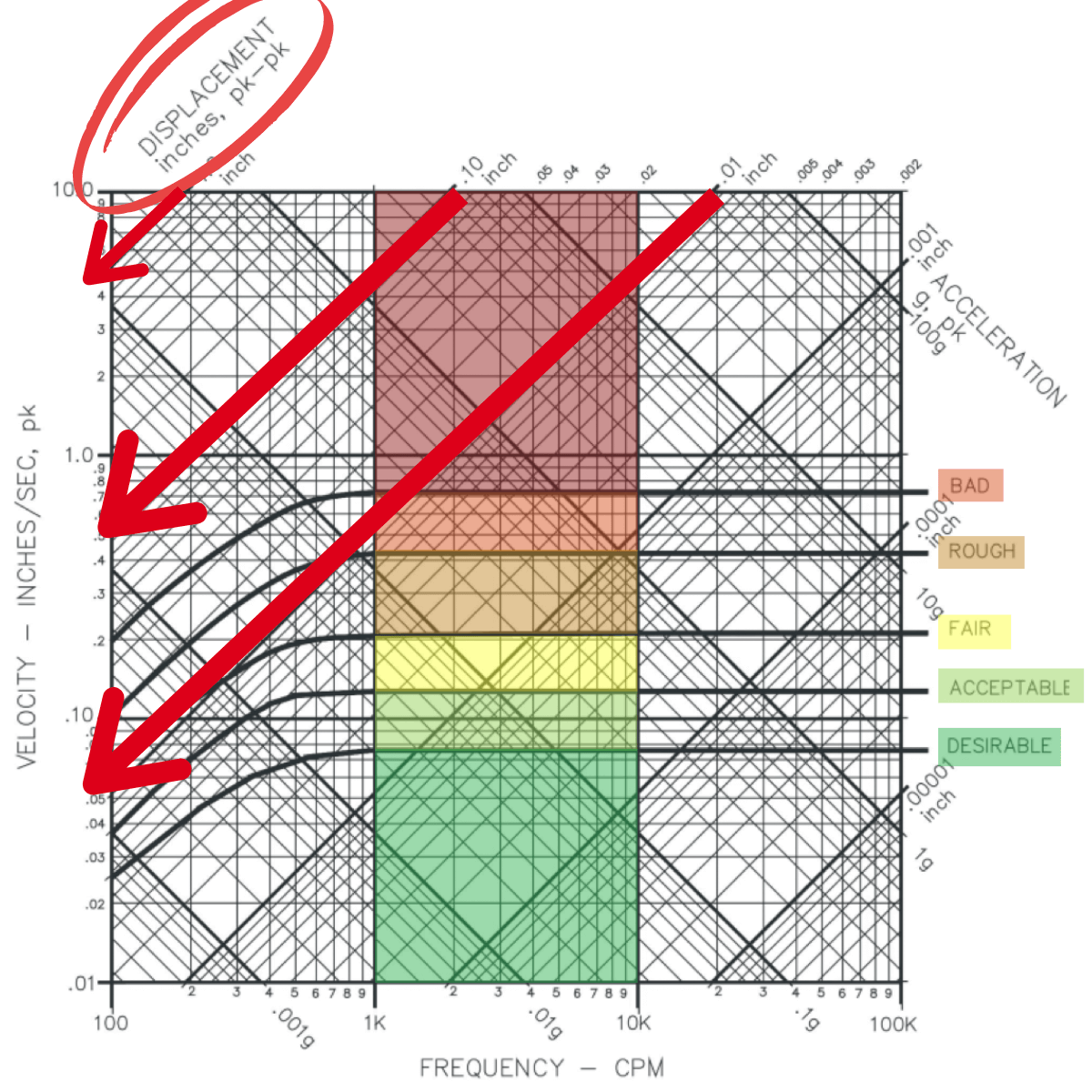

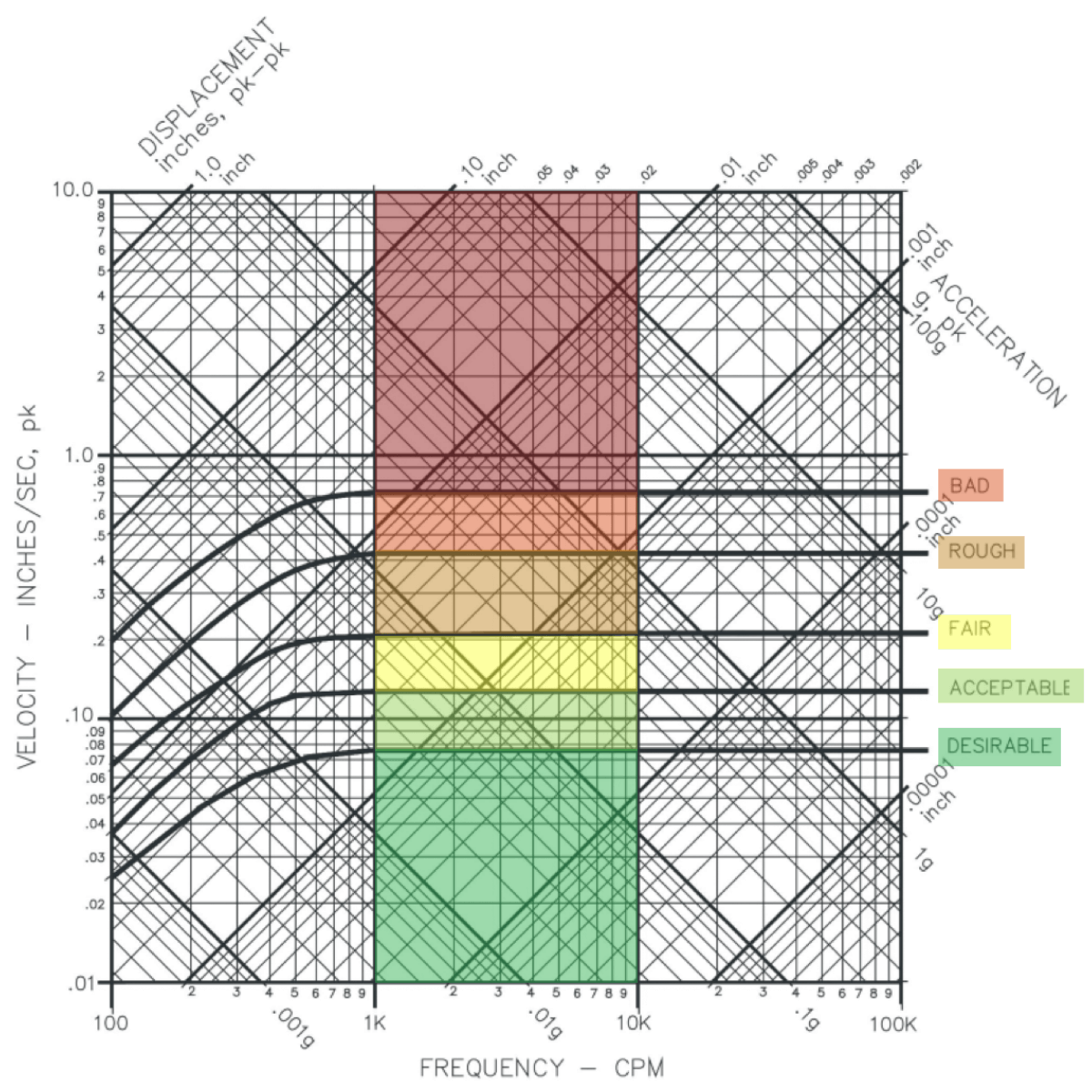

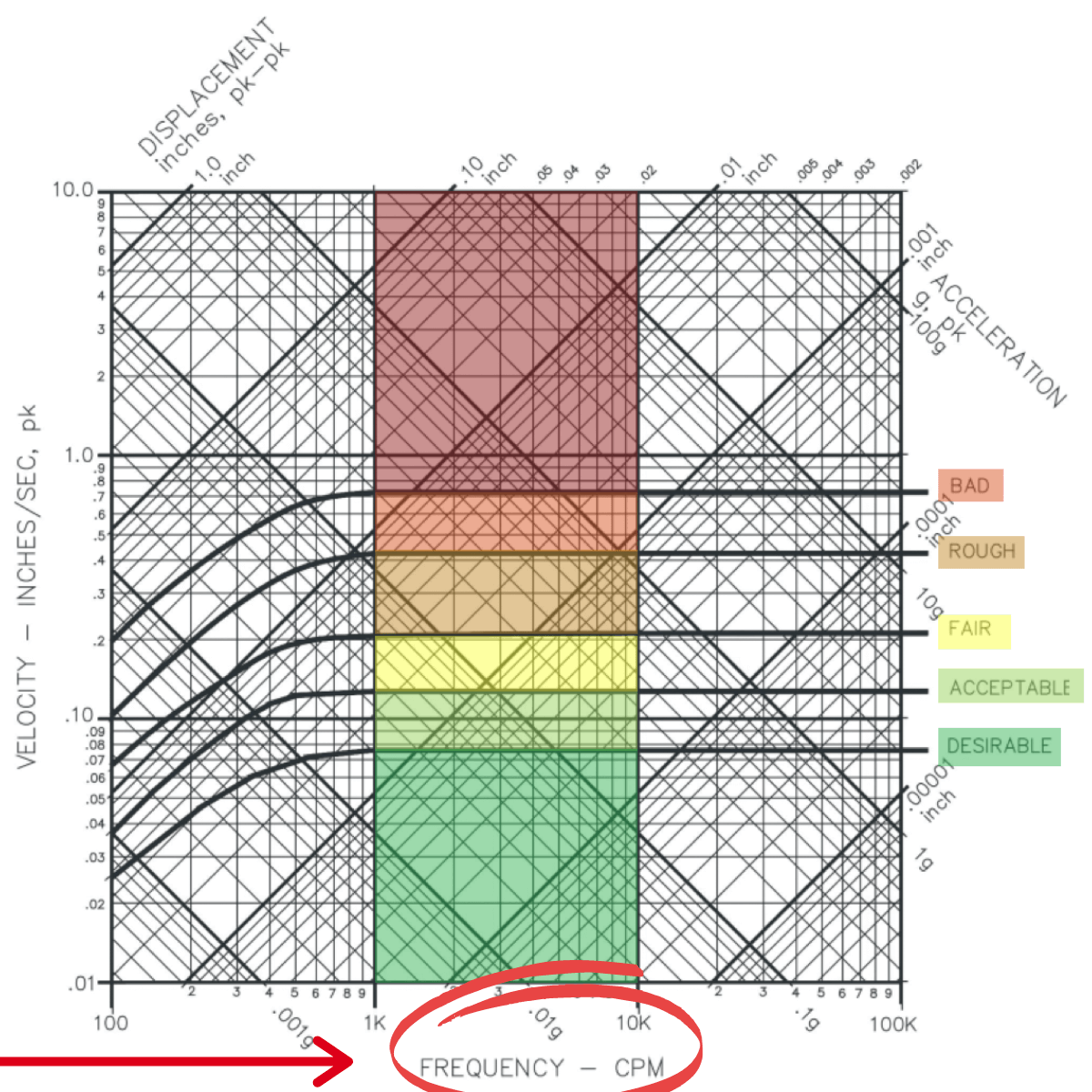

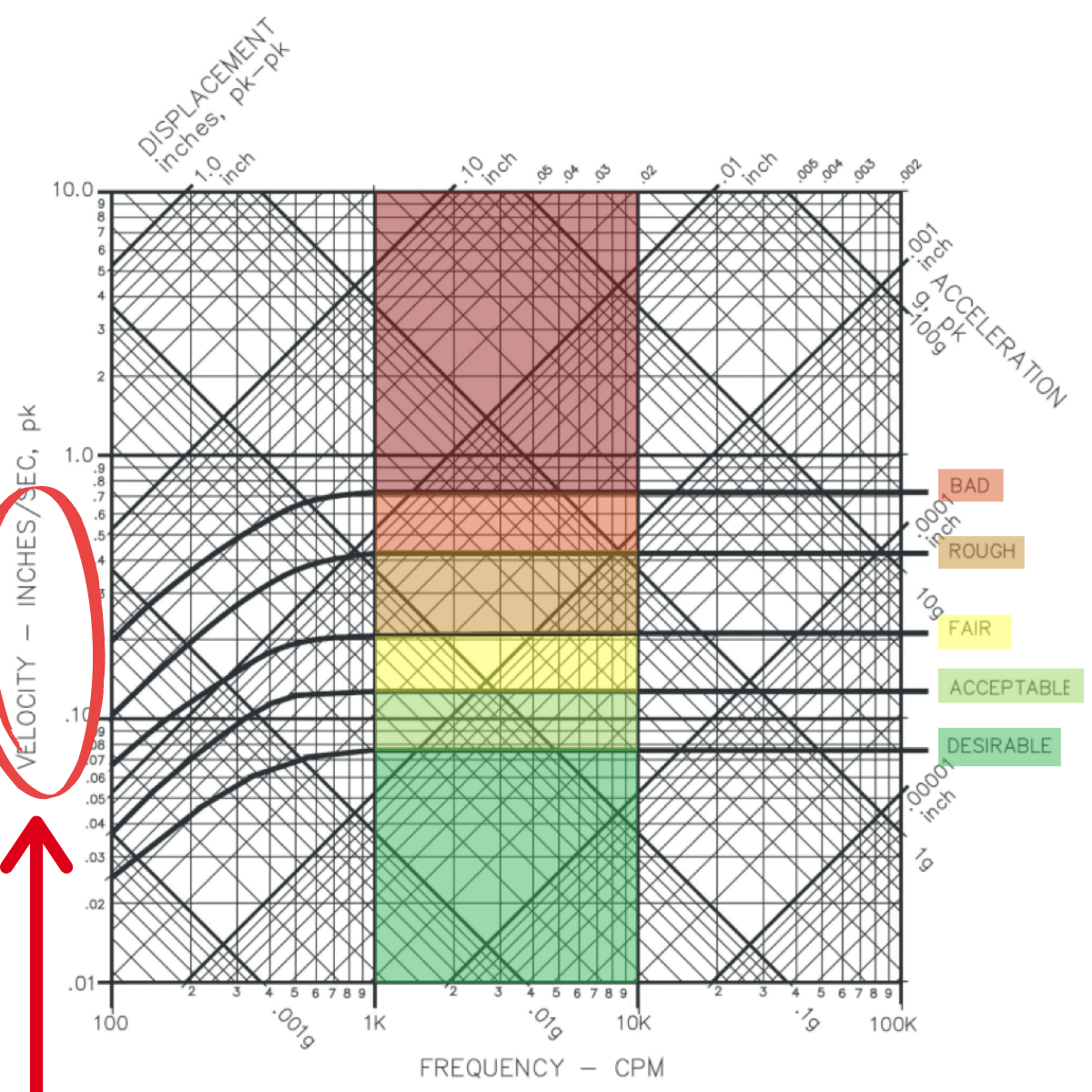

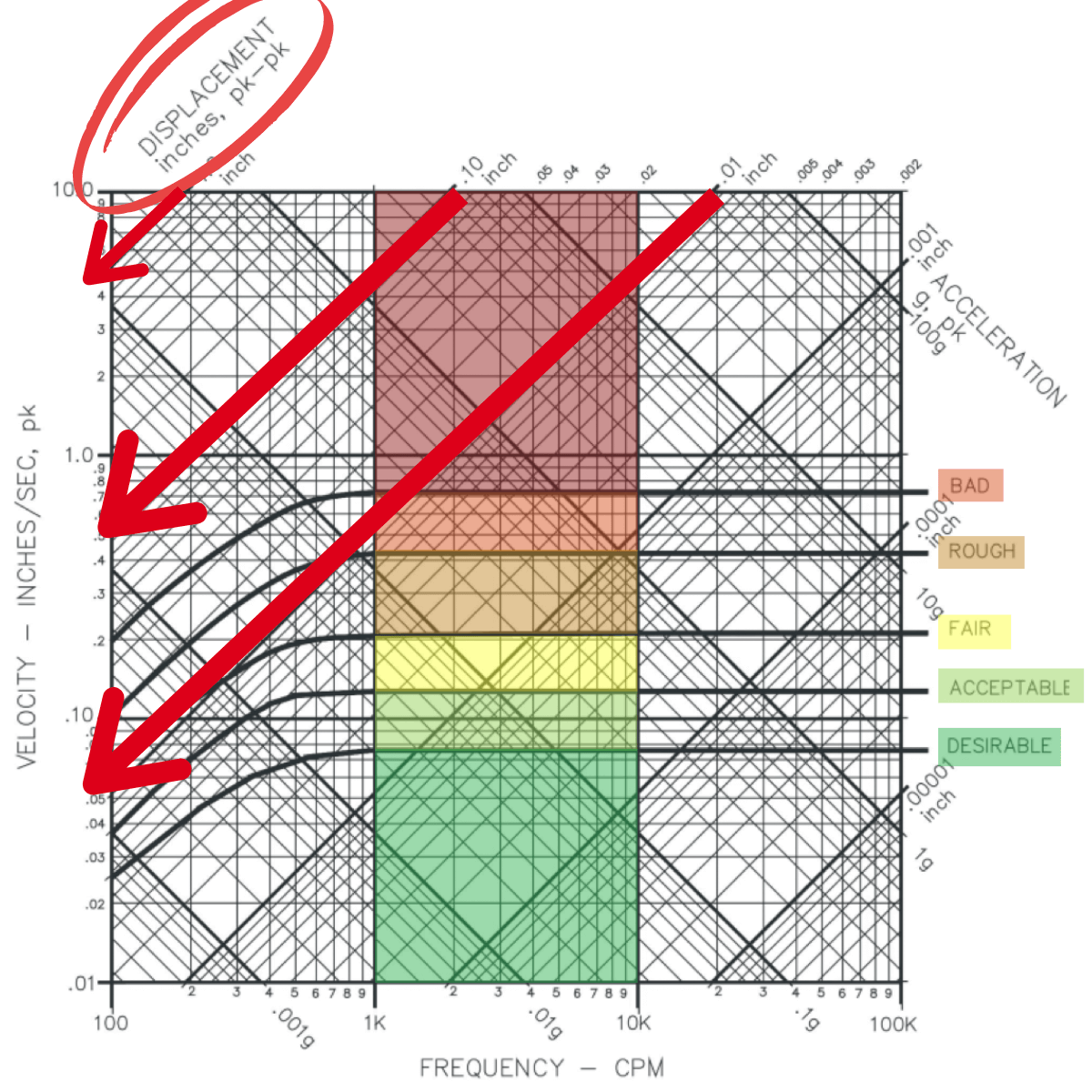

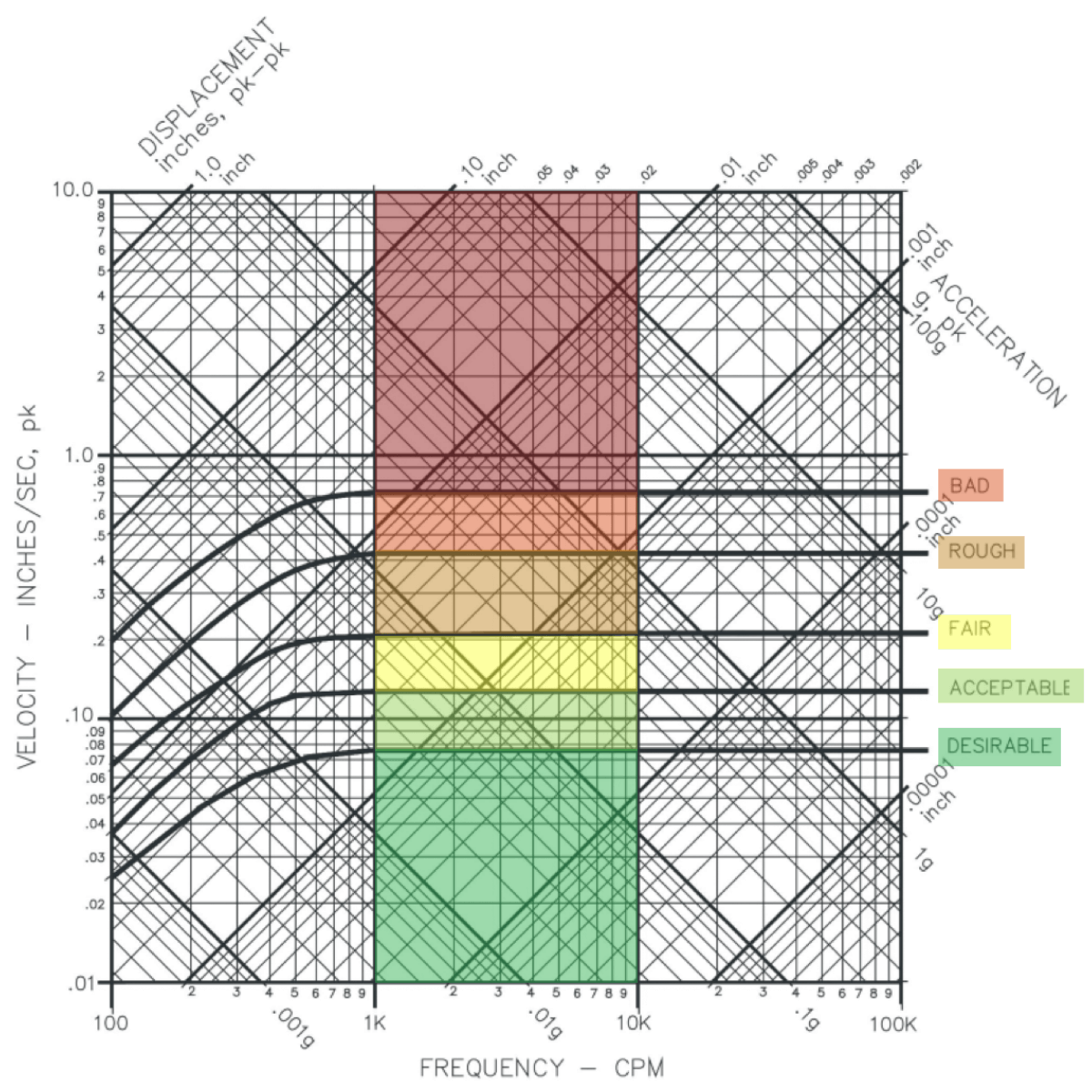

Once you have a measurement of your vibration and level – it might be helpful for you to consider a severity chart.

These charts are used for determining how severe your vibration is and may help you determine your alarm levels at your facility based on standards that are generally accepted across your industry.

This chart shows frequency on the x-axis and increases from 100 cycles per minute up to 100,000 cycles per minute.

These charts are logarithmically scaled.

The diagonal axis shows acceleration and goes from .001g up to .1g.

The vertical axis shows constant velocity and ranges from .01 inches per sec up to 10 inches per second.

The last diagonal axis is displacement and ranges from .00001 inch to 1.0 inch.

Using either your motor speed, machine speed or if you know the frequency of the vibration, you can compare that to the scale on the x-axis. You follow that up the scale, which will show you where the desirable, acceptable, fair, rough and bad levels will fall. This will help you determine where to set your alarm levels based on vibration.

To determine the exact standards for your industry check which common vibration standards are appropriate. Some common vibration standards are: ISO, ANSI, VDI, API, CTI, Hydraulic Inst, EPRI, ASTM, and JIS.

Watch our full virtual training on Vibration Essentials here!

Need assistance? Contact Neal Systems and speak with one of our expert engineers to see which severity chart is right for your plant.

January 4, 2021 | Company News

Neal Systems is happy to announce our recent acquisition of Demcoe Sales. This acquisition, effective January 1, 2021, has added Ed Owens to our NSI team and expanded our expertise in a variety of industries. Ed has 20+ years of experience and has been working closely with our team at NSI for several years, which has made this transition seamless.

This acquisition has expanded our Servomex and JM Canty offerings in the North Jersey and NYC metro areas. Ed Owens has a substantial knowledge of analyzers and will be able to serve our customers greatly with this expertise. Ed also has extensive experience in the pharmaceutical industry, oil and gas, chemical, power and fuel terminals.

This opportunity to grow with Demcoe Sales as a part of the NSI team will open a new door of service and engineering capabilities for our customers. We look forward to growing our team together.

December 7, 2020 | Product News

Polytron 8900 UGLD

The Polytron 8900 UGLD contains an ultrasonic sensor that detects gas leaks regardless of environmental influences, even before a gas detection sensor detects a critical concentration.

The Polytron 8900 UGLD improves safety and efficiency and has a flexible installation with intrinsically safe remote sensor casing with cable also available. The sensor lifespan is 10+ years, which means no sensor replacement in the meantime. The results are easy to interpret as they are shown in percentages and the durable design and fully sealed sensor for reliable use even in harsh conditions.

An HSE study came to the conclusion that 36% of major gas releases and 69% of significant gas releases (0.1 – 1.0 kg/s) are undetected by gas detectors.

“Field trials have indicated that gas plumes in well ventilated areas may not be detected by fixed point or open path detectors. Analysis of hydrocarbon release incidents shows that conventional gas detectors have 65% detection efficiency.”

In the event of a potentially hazardous situation, the measured sound pressure is displayed in an easy-to-understand test value range of 0 to 100% (equivalent to 55 – 110 dBA). This value is easy to interpret, giving you complete transparency over the task at hand.

The Polytron 8900 UGLD triggers the gas leak alarm whenever the ultrasound caused by the gas leak exceeds background noise by 11% for a pre-adjustable period of up to 30 seconds.

Standards and Approvals

IECEx

Ex db [ia] IIC T4 Gb,

-40 ≤ Ta ≤ +40 / +70 °C

CSA

Class I, Div 1, Groups A, B, C, D;

Class I, Zone 1, Group IIC;

T-Code T6 / T4

UL

Class I, Div 1, Groups A, B, C, D;

Class I, Zone 1, Group IIC;

T-Code T6 / T4

ATEX

II 2G Ex db [ia] IIC T4 Gb,

-40 ≤ Ta ≤ +40 / +70 °C

CE markings

ATEX (Directive 2014/34/EU)

Electromagnetic compatibility

(Directive 2014/30/EU)

Low voltage (Directive 2014/35/EU)

Marine approvals

DNV-GL

SIL 2

TÜV Süd certificate

The DrägerSensor® UGLD Ultrasonic Sensor

This unique sensor is PVC coated ceramic piezo, which does not need weather guard. The sensor has a built-in self-test, which runs hourly. A co-centric ring design inner ring reverses polarity to become speaker. The sensor has calibration memory, built-in temperature sensor, and an intrinsically safe design that is field replaceable without declassifying area.

Models and Accessories

Polytron 8900 UGLD (Ultrasonic Gas Leak Detector) and Polytron 8900 UGLD (Ultrasonic Gas Leak Detector with Remote Sensor)

Calibration Kit – for regular functionality checks

Field Survey Device – pre-installation background noise analysis

Commissioning Test Device – enables you to create leak simulations of up to 100 g/sec

Draeger Polysoft Software – facilitates configuration and readout of the Polytron 8900 UGLD

For more information on the Polytron 8900 UGLD, contact us at sales@nealsystems.com!