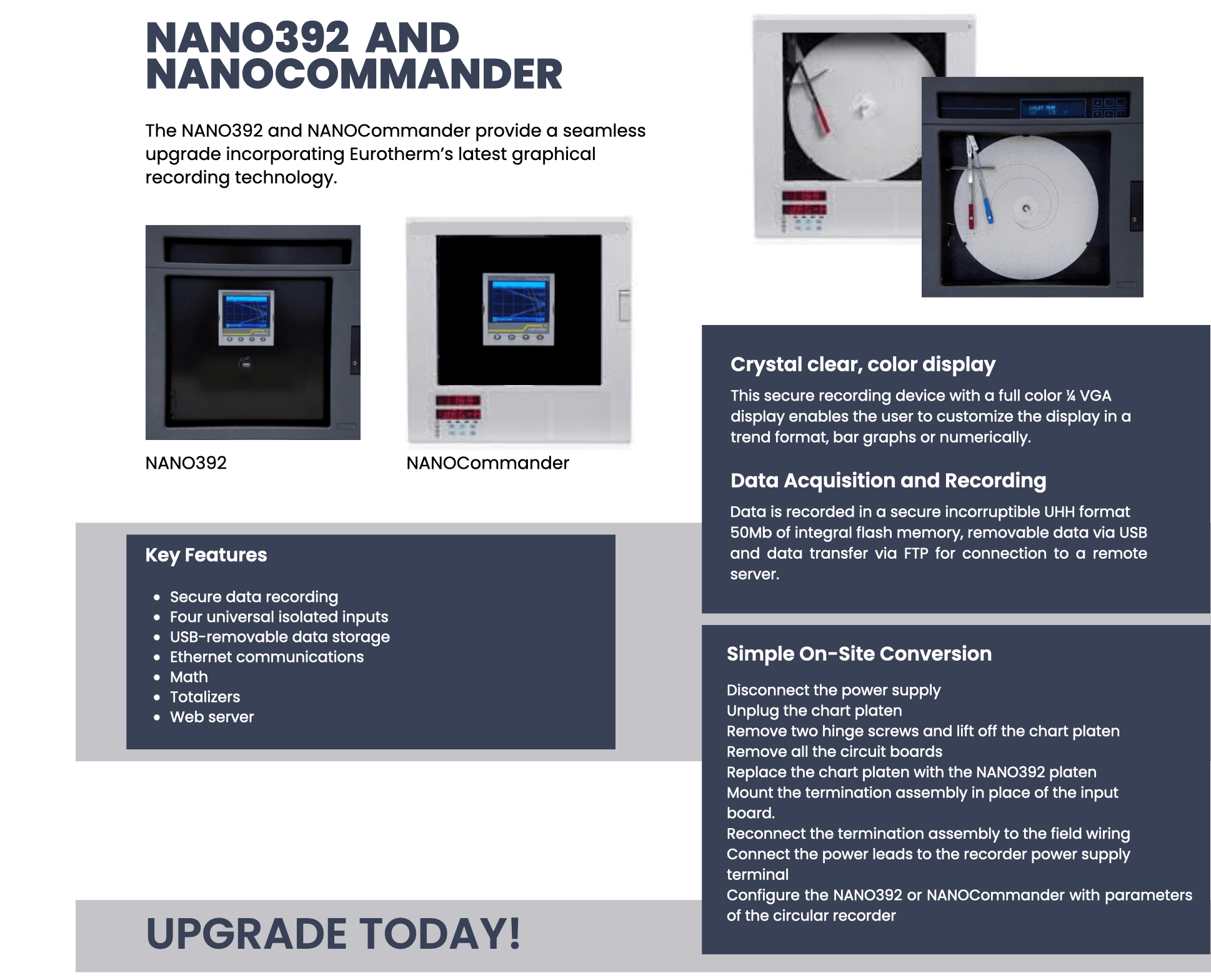

Upgrade your paper chart recorders easily with the NANO392 and NANOCommander

November 9, 2022 | Company NewsProduct News

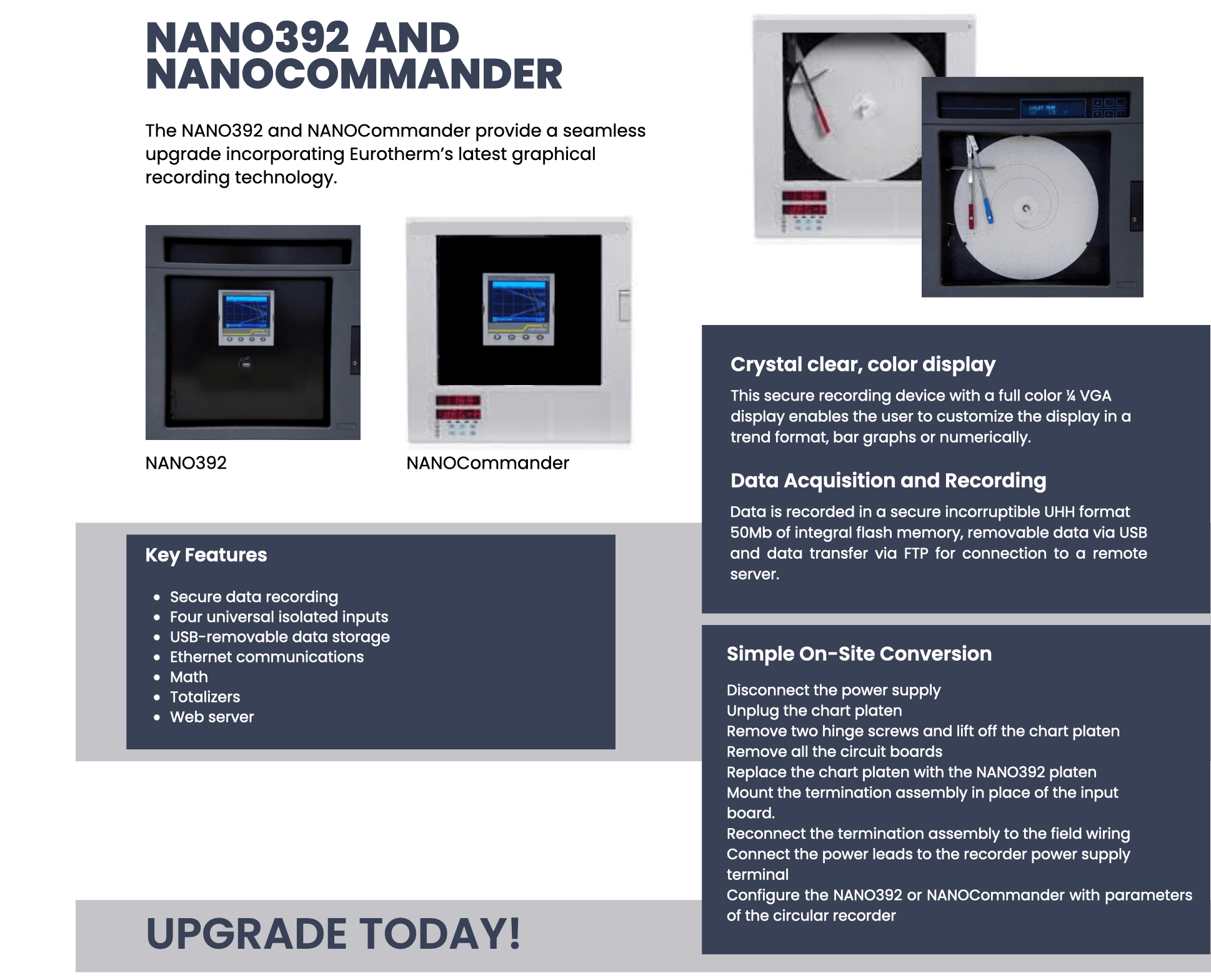

GE MDS has announced a March 31, 2023 launch date for the next generation of unlicensed 900MHz transceivers, TransNEXT. GE MDS is planning to accept TransNET orders until December 31, 2022. Please consider purchasing spares soon to cover the three month gap.

Due to this obsolescence GE MD will be launching the GE TransNEXT.

This is the next generation of unlicensed 900Hz.

Why choose TransNEXT?

Key Features:

Interested in placing TransNET orders prior to obsolences or getting more information from our team on the TransNEXT?

Neal Systems is here to service all your wireless communication requirements!

The PMC VersaLine VL2000 Series submersible level transmitters are specifically designed for use in wastewater, pump/lift station applications.

The ceramic sensing element provides a rugged flush open face design which avoids clogging or sludge build up from the materials often encountered in wastewater. The stainless steel construction will satisfy most applications, but an option of Titanium is available where the chemical environments dictate. The standard polyurethane vented cable is molded to the transmitter providing the highest integrity waterproof assembly well proven in thousands of installations worldwide. FEP cable is available as an alternate for harsh environments. A feature of the VL2000 Series is full scale ranges as low as 10” WC.

Applications Include:

Surface and Run-Off Water

Process Plant and Water Run-Off Monitoring

Sewage Lift Stations – Ceramic Clog Free

Paper Making Machine

Specifications:

Ranges: Full Scale (Zero based)

0-10, 20, 30, 50” WC

0-1, 5, 10, 15, 30, 50, 100, 150 psig

Other ranges and pressure units can be specified.

±0.1%, ±0.25% Accuracies

All welded 316L SS or Titanium

4-20 mA, 2 wire output

Molded polyurethane

For Zero Maintenance:

In order to reduce on site maintenance PMC has developed the MP 11 Moisture Protection Reference Volume. For vented gauge transmitters this provides a total isolation to the atmosphere by using a custom bladder while maintaining the high performance of the transmitter. This changes volume with Barometric pressure. Totally maintenance free.

For more information on this or similar products, reach out to our expert team of engineers HERE!

GE MDS Educational Seminar including Hands-On Learning

Join NSI and GE MDS in New Jersey and Pennsylvania to learn about new trends, tools and technologies for cellular and ethernet radios

Pennsylvania:

DATE: NOVEMBER 2ND

TIME: 9AM TO 1PM

LOCATION: DOUBLETREE SUITES BY HILTON, PHILADELPHIA WEST

640 FOUNTAIN ROAD

PLYMOUTH MEETING, PA 19462

Register now! Email Shane Filer: sfiler@nealsystems.com

New Jersey:

DATE: NOVEMBER 3RD

TIME: 9AM TO 1PM

LOCATION: HILTON GARDEN INN

304 US-22

SPRINGFIELD, NJ 07081

Register now! Email Shane Filer: sfiler@nealsystems.com

What to expect…

Next Generation TransNEXT Highlights & Orbit Platform enhancements

Software Tools for Programming and Operation

Best Practices: Troubleshooting

See Job Note pdf here!

Problem: An industrial gas company had ten ovens with 1980’s technology. None of the ovens were networked together and there were no drawings for most of the ovens. Over the decades, multiple minor wiring modifications had turned each enclosure into a bird’s nest of unintelligible wiring. When something went wrong, it took maintenance hours to troubleshoot.

Each of the ovens had the following specifications:

34″ x 22″ x 44″ Chamber

2350 degrees F Max Temp +/-20 degrees F Uniformity

Electric Heating Elements with Solid State Power Controllers

48KW @ 480/3/60 60 Amps

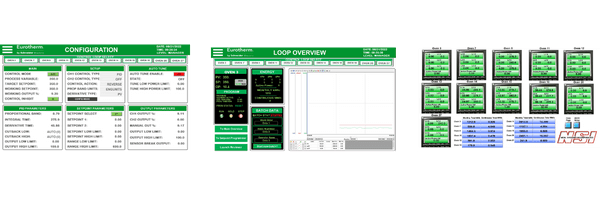

Vertical door with Electric Gear Motor

Solution: NSI worked in conjunction with L&L Furnace of Aston, PA to upgrade the entire control system. The chosen solution involved supplying controller / recorder solutions with the Eurotherm Nanodac, adding power monitoring with the M-System 53U power meter, networking all the ovens together and displaying all SP’s, PV’s and alarms on a centralized 15” Weintek OIT, generating a powerful local notification system using the M-System IT60SRE Modbus TCP driven stacklight, and providing a cloud–based historian and remote alarming using a SCADACore Viacell edge device. Everything was then tied together with Eurotherms’ ‘out-of-the-box’ oven SCADA system. All of this had to be done for a budget that wouldn’t break the bank.

The Nanodac is a large I/O count, cyber–hardened two loop controller with built-in setpoint profiling, function block programming, encrypted data logging and Modbus TCP communications.

Three CT’s were added to each oven and connected to the M-System 53U power meter, which has a Modbus RTU interface. This was connected to a Lantronix converter, thus providing a Modbus TCP interface, allowing massive amounts of power data to be extracted, stored and analyzed.

The Weintek display is used as a central operator station to show profile status, alarms and current oven temperatures for all ten of the ovens.

The M-System IT60SRE Modbus TCP stacklight was delivered with four lights. Each light can be off, solid or flashing and all driven by Modbus commands. This gives the operator a wealth of available messages using combinations of lights and light states and all done with just power wiring and a Cat5 cable. This again, reduces installation time, materials and subsequently cost.

The SCADACore Viacell communicates to all ten Nanodacs over Modbus TCP and sends status, temperature and alarm information to the cloud. This is used as a back-up historian and to alert supervisors to any alarms.

The Eurotherm Oven SCADA system automatically recognizes the Nanodac controller and all relevant parameter addresses are pre-programmed. With its pre-built graphical interfaces, this means that a complete SCADA system can be developed in a day and commissioned over a second day thus reducing the project costs drastically.

During the installation process, all the surplus wiring was removed, remaining wiring tidied up and traced. ‘As-built’ AutoCAD drawings were then developed and delivered to the customer as part of the sign-off package.

End Result: The customer is now able to see both temperature controls and energy meters from every networked furnace from their control room. Within the first month, they were able to quickly see broken heater elements such that they did not have to start / restart oven runs multiple times.

Contact us today if you have old furnaces or ovens with controls that need to be networked and upgraded!

See Job Note pdf here!