Company News

March 16, 2021 | Company News

Neal Systems is now representing Automation Service for all customers throughout eastern Pennsylvania, Maryland, New York, Delaware, and New Jersey. This addition allows Neal Systems to better serve our industrial customers with the highest quality, shortened lead time and competitively priced remanufactured process control solutions, as well as NEW Foxboro pneumatic instruments.

Automation Service offers a 2-to-3-week standard delivery, a savings of 40-70% on comparable repairs, reliable products, and a 2-year service warranty. The remanufactured products are originally manufactured by Foxboro, Fisher, Rosemount, Honeywell, AMETEK, and Micro Motion. The Foxboro line now includes both new and remanufactured pneumatic transmitters: 43AP, 11DM/GM, 13A, 13FE, and 15A, as well as other pressure transmitters and controllers. There also is a recycling program for your facility where you can receive payment for returns on all of the equipment above.

We know our customers prefer using some products that may no longer be available or have extraordinary repair costs. Automation Service is the perfect solution to keep your tried-and-true products up and running in your plant.

If you have a control valve, actuator, positioner, controller, transducer, regulator, transmitter, magnetic flowmeter, flowtube, vortex flowmeter, or recorders that needs replaced, contact us for a quote for a remanufactured solution!

February 16, 2021 | Company News

Eurotherm offers a comprehensive range of scalable and flexible solutions which will satisfy the requirements of environmental and stability chamber monitoring for Pharmaceutical and Bio-Pharma industries. These solutions unify the environmental and security data from the manufacturing area for presentation to plant or laboratory managers and operators.

See the application note related to these products here: Pharmaceutical Environmental & Stablility Chamber Monitoring

January 22, 2021 | Company News

Welcome Stephen Mangiaracina!

Stephen is the latest addition to our applications team. In the roll of Junior Applications Engineer, he will be working closely with our engineering and solutions team to provide our customers the most efficient and reliable solutions for their applications.

Stephen has been working with Neal Systems as an intern where he has had gained experience with SCADAPacks, GeoSCADA, and Elpro radios. He also is responsible for executing over fifty Samsara pump efficiency integration dashboards for one of Neal Systems largest ongoing projects.

We are happy to have Stephen on board, which will give us the ability to better serve our expanding customer base!

January 13, 2021 | Company News

If your facility utilizes large rotary machinery such as pumps, compressors, fans, blowers, or turbine/generator sets, this presentation is for you!

John Lamp, Neal Systems Technical Lead, will be presenting at the Engineers Joint Committee of Long Island’s Engineers Week Webinar Series on good vibration practices and modern technologies that can help monitor and alarm on significant vibration events and trends. The goals of this presentation are to teach a basic understanding of the fundamental concepts behind vibration monitoring and provide exposure to examples of modern technological solutions available in the industrial market, including wireless vibration sensors, with a focus on the strengths and weaknesses of different types of technology.

This course will count for 2 PDH credits.

A variety of courses are being offered. See the full schedule and how to sign-up here!

January 5, 2021 | Company News

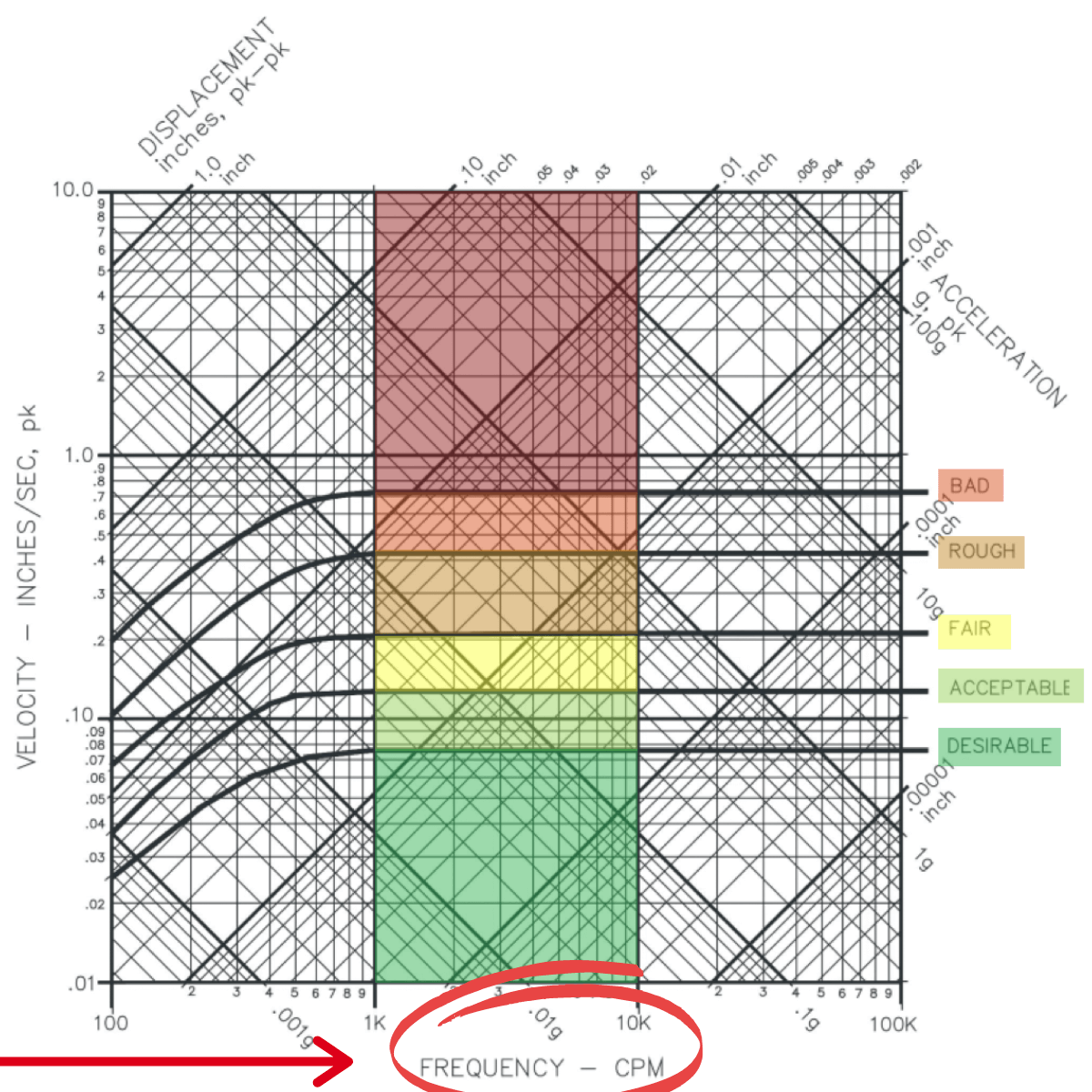

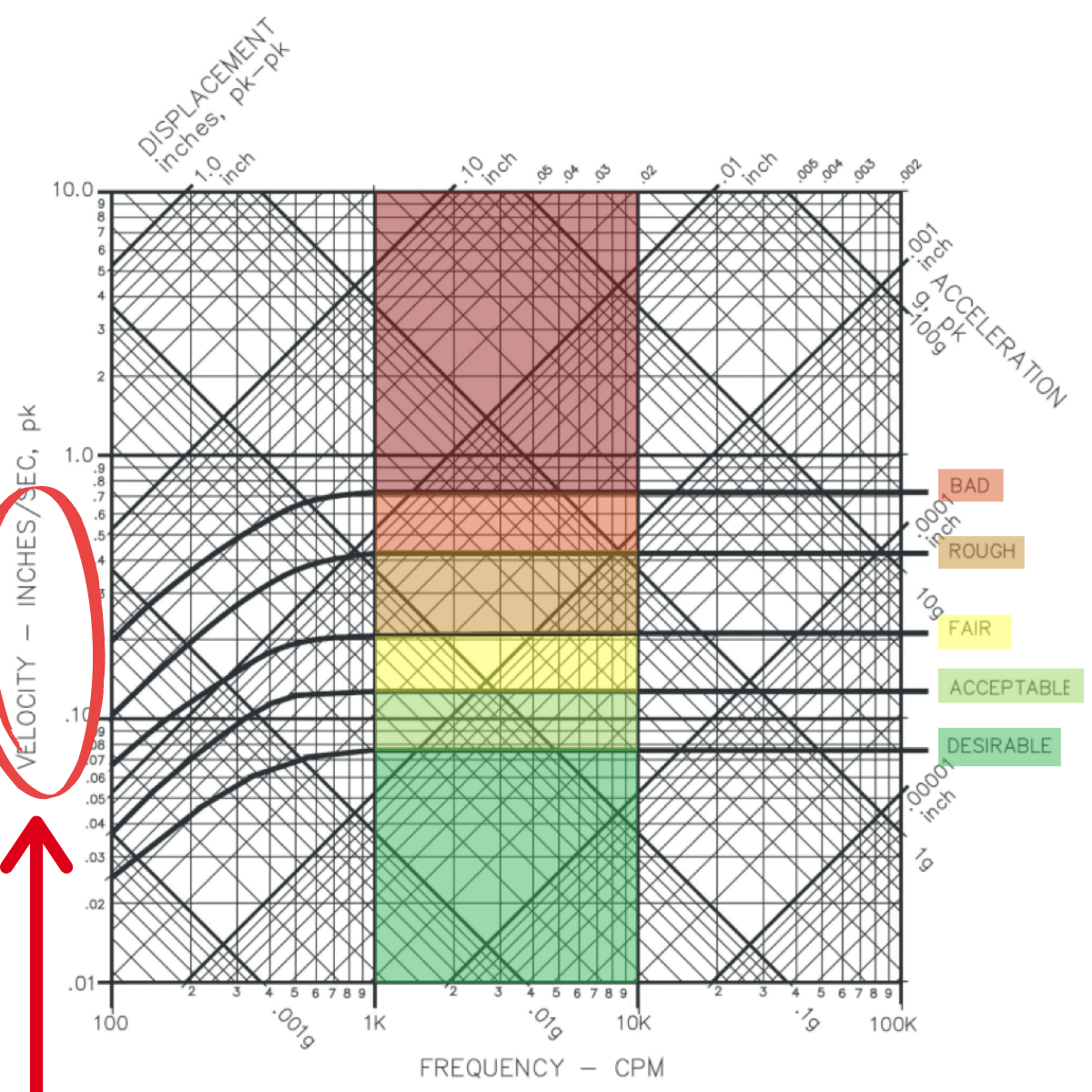

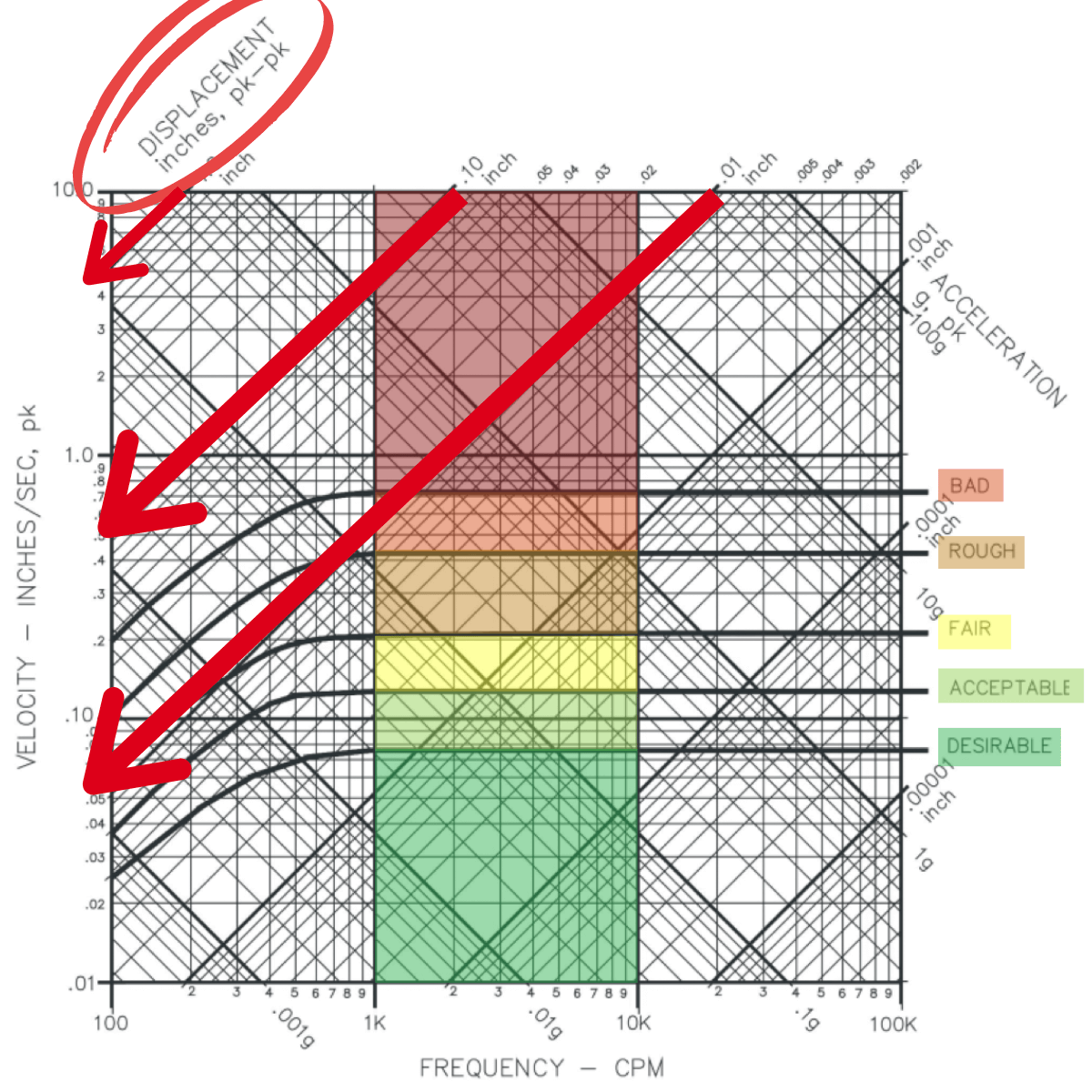

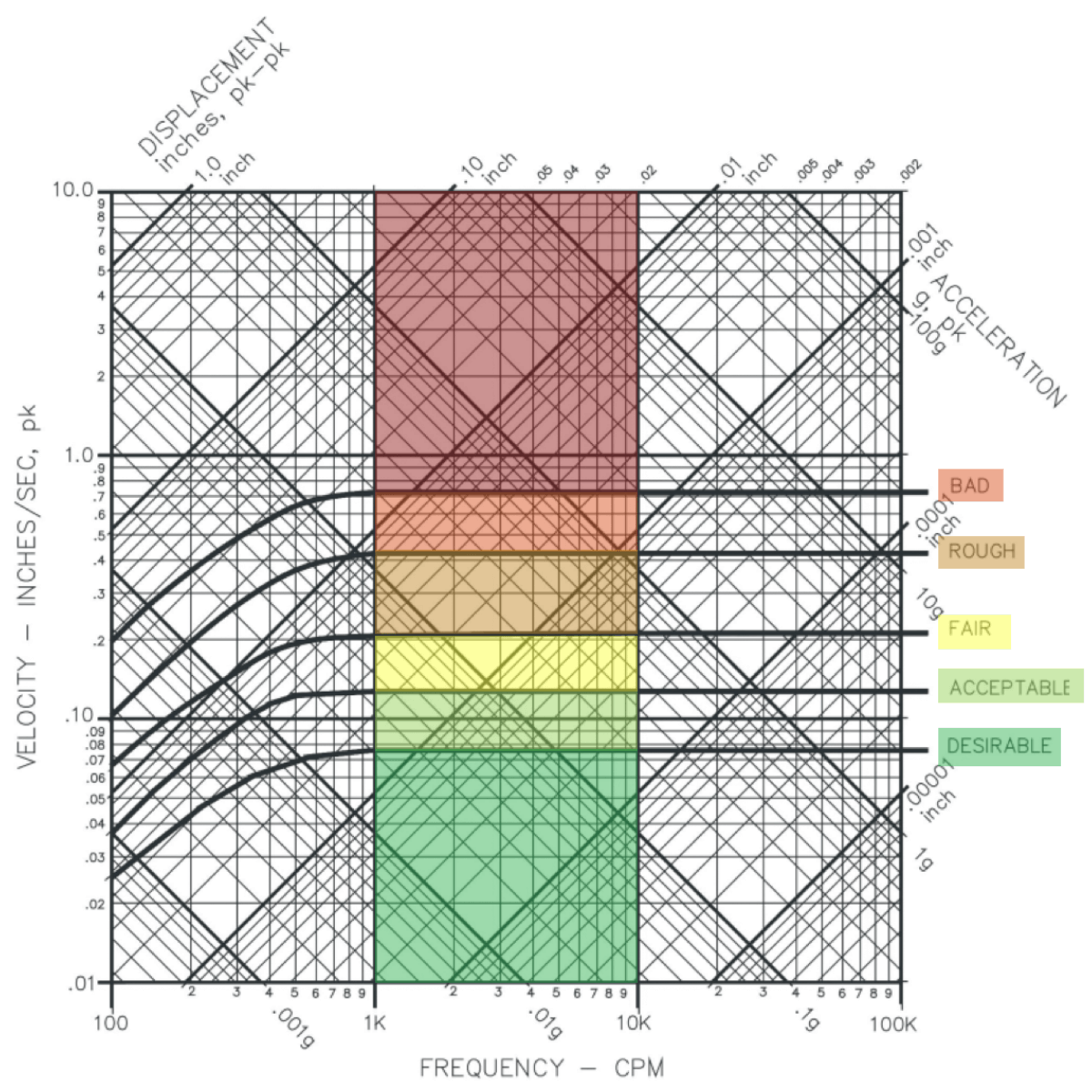

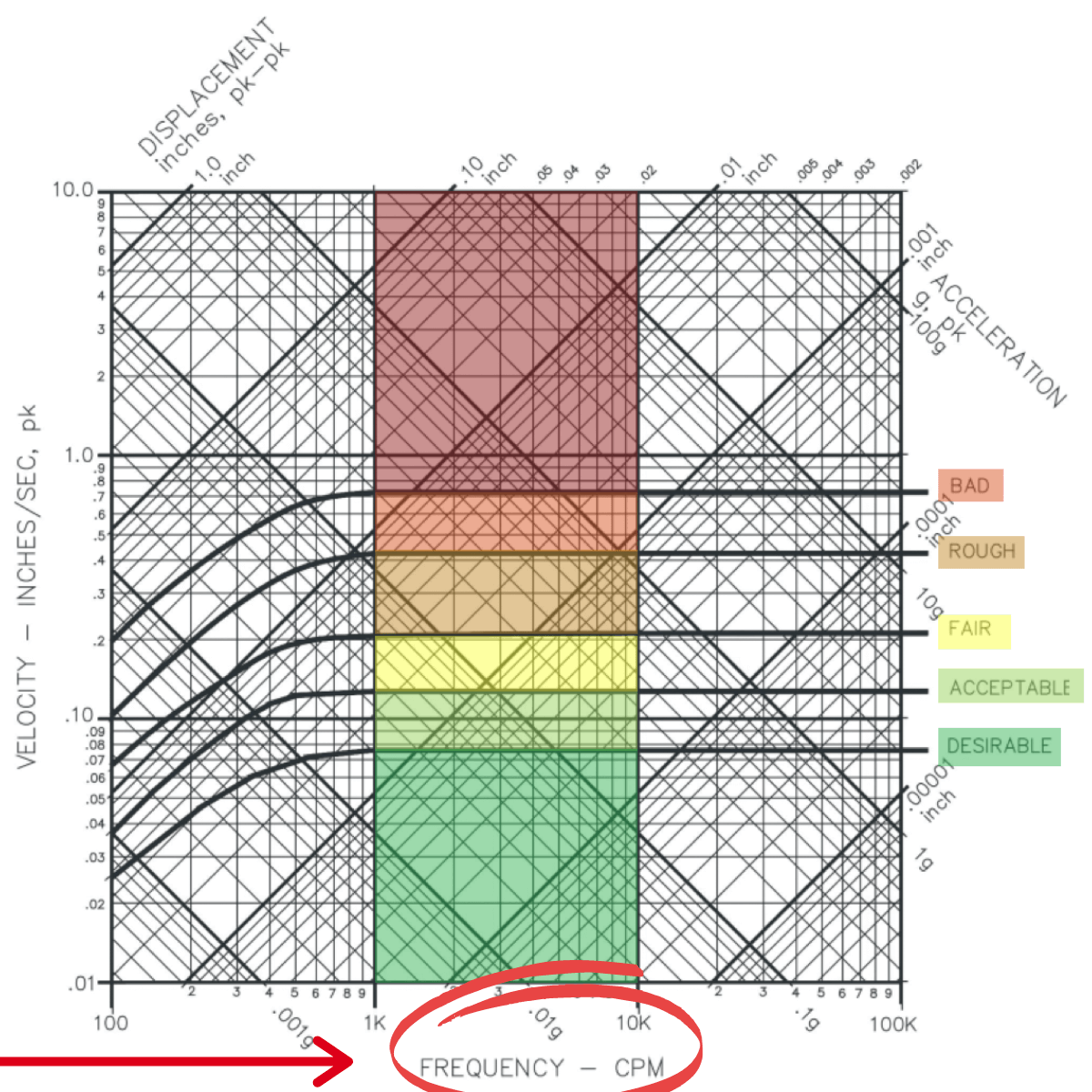

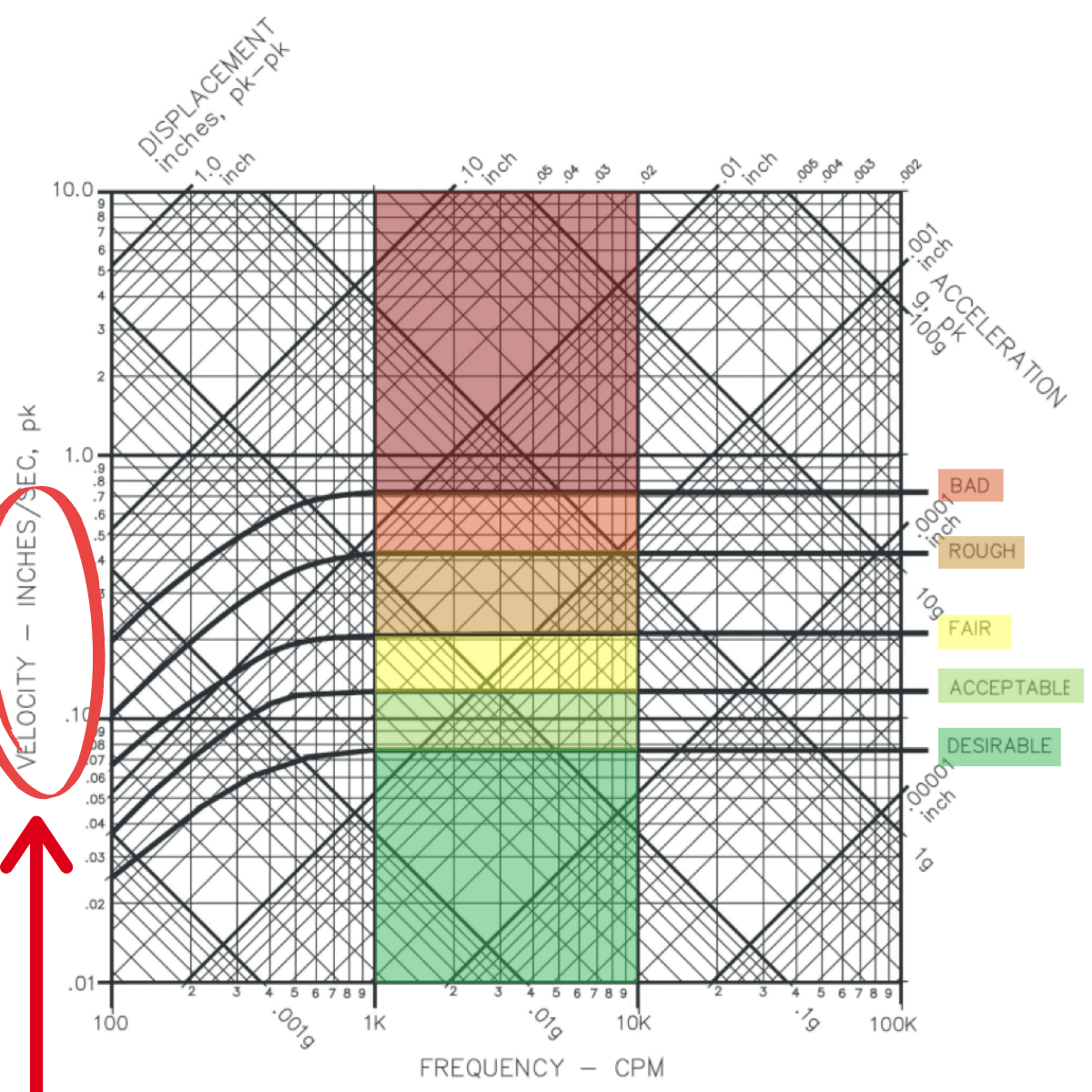

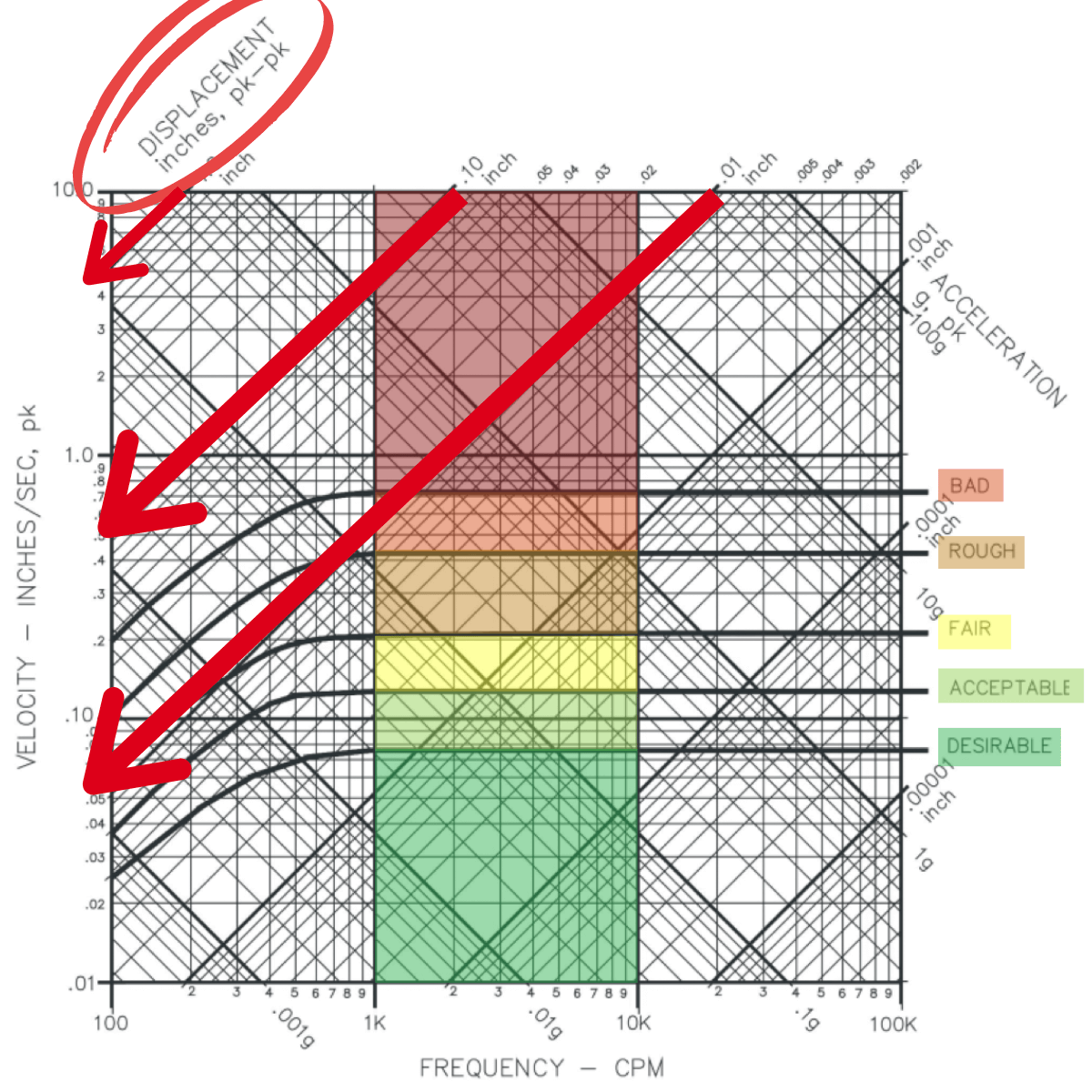

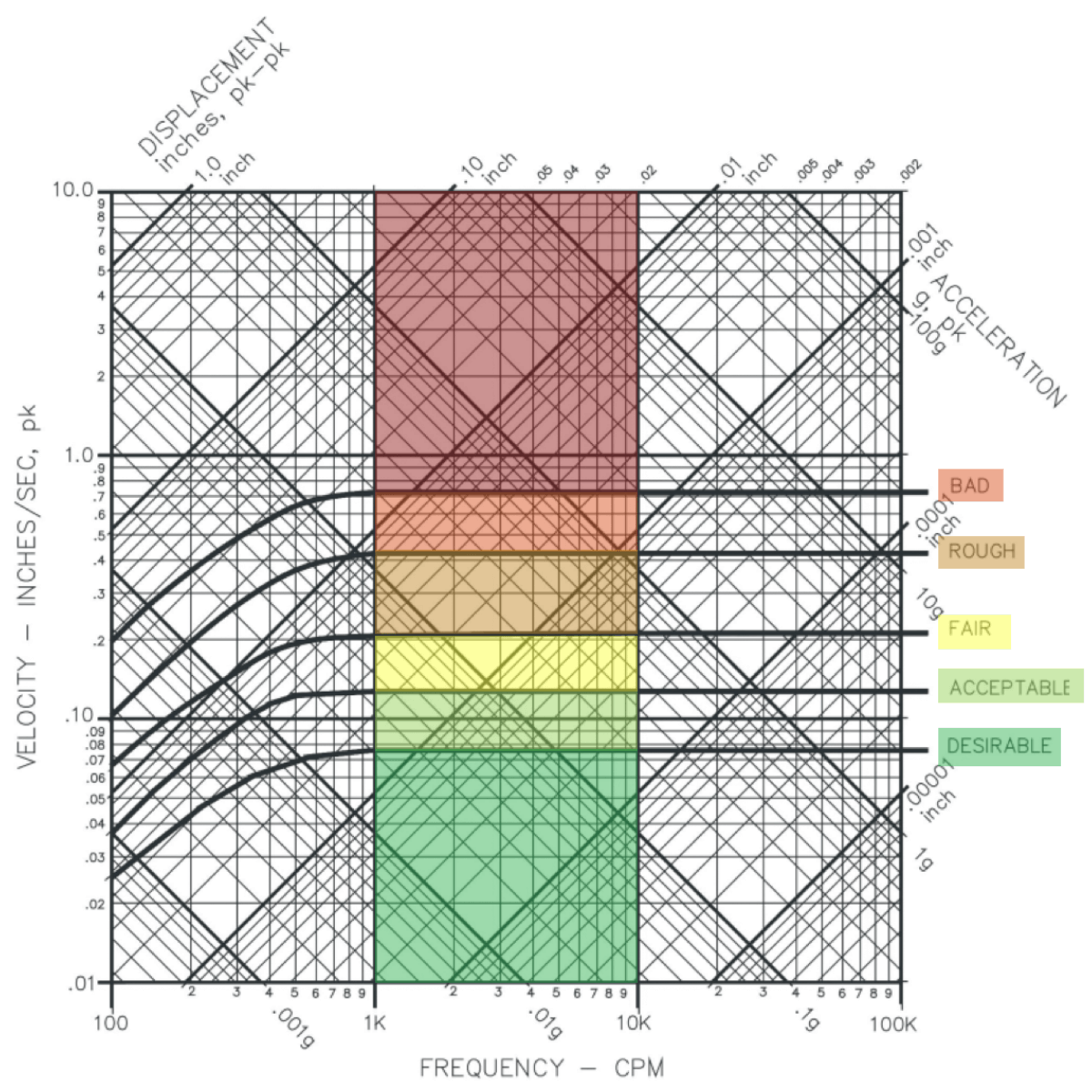

Once you have a measurement of your vibration and level – it might be helpful for you to consider a severity chart.

These charts are used for determining how severe your vibration is and may help you determine your alarm levels at your facility based on standards that are generally accepted across your industry.

This chart shows frequency on the x-axis and increases from 100 cycles per minute up to 100,000 cycles per minute.

These charts are logarithmically scaled.

The diagonal axis shows acceleration and goes from .001g up to .1g.

The vertical axis shows constant velocity and ranges from .01 inches per sec up to 10 inches per second.

The last diagonal axis is displacement and ranges from .00001 inch to 1.0 inch.

Using either your motor speed, machine speed or if you know the frequency of the vibration, you can compare that to the scale on the x-axis. You follow that up the scale, which will show you where the desirable, acceptable, fair, rough and bad levels will fall. This will help you determine where to set your alarm levels based on vibration.

To determine the exact standards for your industry check which common vibration standards are appropriate. Some common vibration standards are: ISO, ANSI, VDI, API, CTI, Hydraulic Inst, EPRI, ASTM, and JIS.

Watch our full virtual training on Vibration Essentials here!

Need assistance? Contact Neal Systems and speak with one of our expert engineers to see which severity chart is right for your plant.