Application Note: Designing A Wireless SCADA System for a Municipal Water Plant

May 3, 2023Abstract

A large water filtration plant was in need of a wireless control system for their 20 pumping stations scattered a few square miles apart from each other. Their previous system was failing and hardware was no longer being supported. Operators would run from pump to pump, hoping to catch any issues before they became bigger problems. Moreover, the growing forests and terrain made it difficult for the radios to communicate effectively. Neal Systems redesigned and built them a brand new system, migrating their system to the new one while keeping the existing one operating as possible.

Task

Their new system needed to control, record, and monitor data from their pumps i.e. flow, pressure, well depth, etc. Regulations require monthly pump data, so the ability to view historical data and generate reports is vital. The customer wanted to use wireless technology. Ethernet base licensed radio and cellular modems were used to communicate around terrain and forested areas.

Solution

With that in mind, NSI designed a communications network around terrain and trees, and set up radio communications. Elpro radios were used for the licensed radio communications, and Scadacore celluar modems were used where license radio communication wasn’t usable. The communication protocol is DNP3, which allows the plant to view time-stamped data even when the network connection is lost. DNP3 is great for plants that have strict regulatory requirements. The Schneider Electric SCADAPak 474’s were the control PLCs, and GeoSCADA was used for the scada system, allowing them to monitor and control the system and

view historical data. XLReporter was used to create spreadsheet based reports from the GeoSCADA historical data. SCADACore system is used to monitor the system for alarm conditions and call plant operator(s) when alarms occur.

Conclusion

Neal Systems replaced all broken hardware and communication systems, while installing, testing, and programming all of the equipment. NSI also trained their operators on how to use the new system. Operators no longer have to run from pump to pump, as they can now monitor their systems remotely. Most importantly, they are able to record and monitor data with reduced failures. They are better able to see data in real-time, even off network, which reduces downtime. With Neal System’s new design, the water filtration plant is better prepared to meet regulatory requirements with ease.

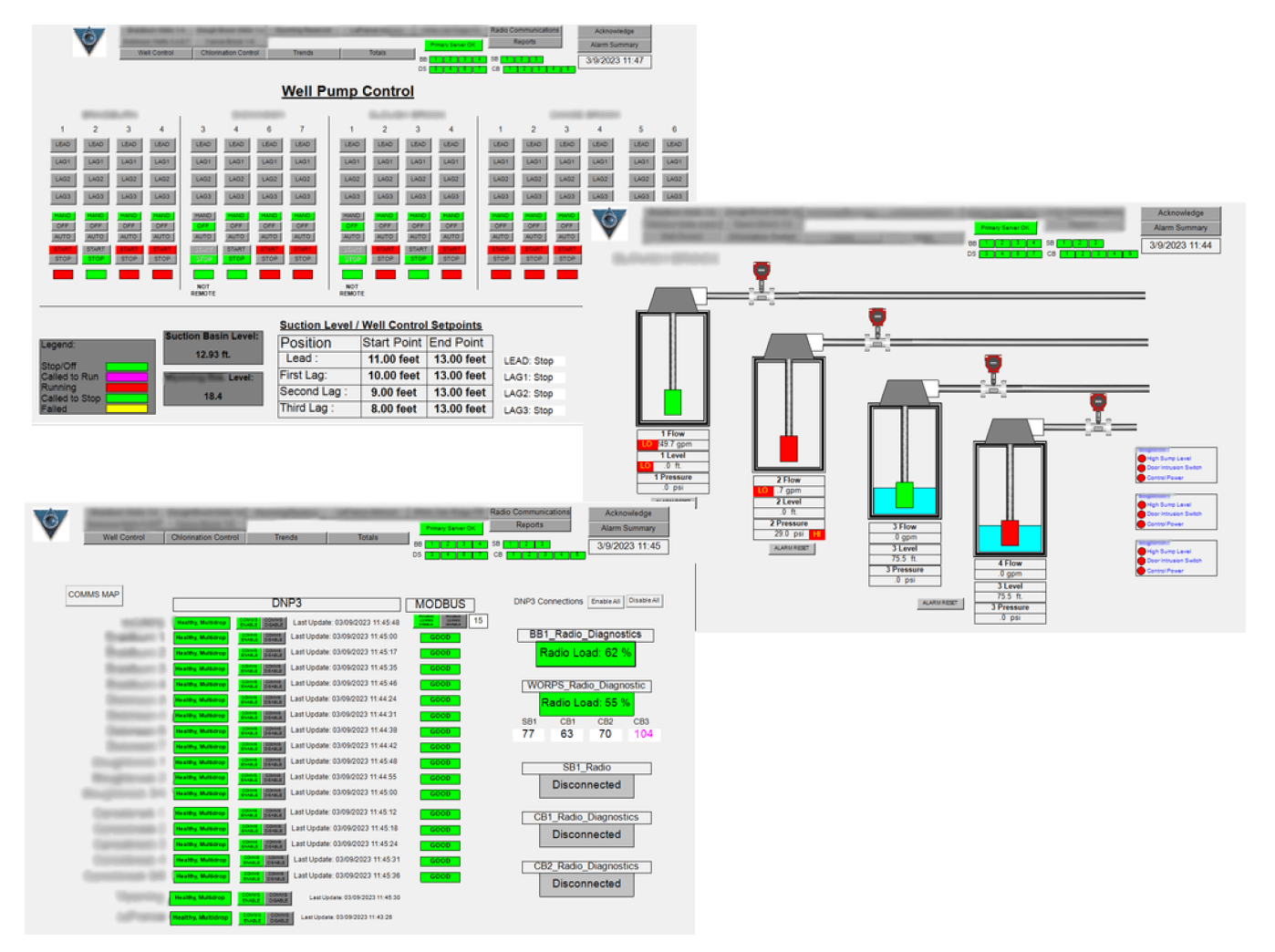

Example Screens

Example Screens