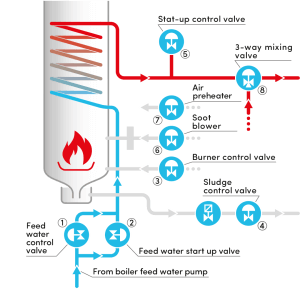

Boilers: Precise Control Valves for Power Plants

February 10, 2022

With ARCA Valves you will find the right control valve for each process step in the boiler of the power plant.

1) Main/feed water control valve

With this control valve, the level in the boiler drum is regulated so that boiler feed water is continuously available in the boiler for steam generation. In order to compensate for the difference between the characteristic curve of the feed water pump and the operating characteristic of the boiler system, the characteristic curve of the feed water control valve must be designed accordingly.

2)Filling/feed water control valve

The boiler drum is filled by this control valve when the system is started up. Since a large differential pressure and cavitation have to be mastered during start-up, this valve is subject to high stress and thus wear. Therefore, this often small valve is equipped with a hard multi-stage trim and is located in parallel with the main feed water control valve, which must then be designed for maintaining the level.

3) Burner control valve on the boiler

This valve regulates the supply of natural gas to the gas burner or the heating oil to the oil burner on the boiler. During gas operation, the valve regulates to maintain the defined control characteristic and reduce noise. When heating oil is used, this valve functions as an overflow facility and holds the pressure upstream of the oil burner nozzle constant.

4) Sludge control valve

This valve quickly opens for a brief moment to drain a small quantity of boiler feed water for desludging the boiler water drum. Hard internal parts are required to withstand the high differential pressure, cavitation, and abrasion that prevail. The seat faces of this control valve are subject to wear, which is why we recommend installing an additional shut-off valve here.

5) Boiler start-up control valve

The start-up control valve typically blows steam through a silencer system into the atmosphere when the boiler plant is started. Since the steam expands with a high-pressure reduction, this valve usually has an asymmetric design.

6) Soot Blower Control Valve

The walls of the heat exchangers in the boiler are steam-cleaned of soot particles to optimize heat transfer efficiency inside the boiler. To this end, soot blower control valves feed live steam to the soot blower nozzles with minimum actuating time.

7) Air preheater control valve

The burner air is preheated to optimize the effectiveness of the combustion process. The temperature of the burner air is determined by the steam fed to the air preheater via this control valve.

8) 3-way mixing valve

Superheating the steam of the steam turbines while they are running increases plant efficiency and prevents the turbine blades from becoming damaged by condensed drops of liquid. For better energy utilisation of the generated steam, secondary overheating is installed in power plants with higher steam pressures. The heat transferred to the superheater varies greatly due to fluctuating loads and soot deposits in particular. The temperature of the superheater must therefore be regulated. The superheated steam is passed through a pipe coil by means of the 3-way mixing valve, which is located in the water-filled part of the steam drum. The colder drum water with the saturated steam temperature thus cools the superheated steam.

8) Boiler injection cooler

Another way of controlling the superheater temperature is usually implemented in new systems by injecting boiler feed water with a controllable injection cooler.