February 10, 2026 | Product News

Weighing and feeding equipment is critical in the cement industry to provide accuracy, process stability, product quality, and energy efficiency. The cement industry requires robust, specialized conveying and feeding equipment to handle a variety of bulk materials, including abrasive materials ranging from limestone to fine powders. The equipment must provide continuous and precise flow of materials and operate in extremely harsh and strenuous operating conditions.

Cement manufacturers rely on rugged and durable conveying and feeding equipment in each step of the process. They must accurately track and measure inbound raw materials (e.g., gypsum, clinker, silica and limestone) and closely monitor in-process material consumption. In addition, precise ingredient blending and accurate final-product dispatch is also critical to product quality and operational efficiency.

Conveying Equipment

Robust conveying equipment is essential, it is used to transport materials between different stages of the production process, and the distances can be far. Belt conveyors are the most common and versatile conveyors used for long-distance and high-capacity transport and continuous and precise feeding of bulk materials such as limestone, clay and clinker. These heavy-duty conveyors can be run horizontally or on an incline and utilize robust belts and components that are heat-resistant, durable and designed to withstand harsh environments. These Conveyors also often incorporate Belt Scales to continuously measure the mass flow of the bulk materials and these must also be extremely durable while able to consistently and accurately provide critical process data.

Bucket Elevators are used for vertical transport to lift materials like raw meal, clinker and finished cement from a lower point in the production process to a higher one. They are compact and have a tall lifting range to move material, such as feeding material into a grinding mill or storage silo.

Pneumatic Conveying Systems use air pressure (or vacuum) to move powdered materials (like finished cement) through sealed pipelines over long distances. They offer excellent material containment, preventing dust emissions and their pipelines can be routed around obstructions but these systems do require additional equipment including blowers and air filters.

For short-to-medium distances, Screw Conveyors can be used to transport fine, powder-like materials, such as fly ash, cement, and dust. They have a rotating screw inside a trough or tube and are ideal for controlled volumetric feeding and dust containment.

Feeding Equipment

Feeding equipment is required to extract material from storage (hoppers or silos) and to deliver it continuously and uniformly into process machines such as crushers, mills, or kilns at a precise, controlled rate.

Vibratory Loss-in-Weight Feeders are suitable for feeding bulk materials, such as coarse limestone, before they enter a crusher. Vibration is used to move and regulate the flow of the material, including irregular shapes, larger particles, pellets, and powders.

Table Feeders are used to extract and feed smaller, granular or powdery non-sticky materials from silos or hoppers with an adjustable flow rate, often for blending purposes.

More robust heavy-duty apron feeders that use metal plates (aprons) linked by chains serve to extract and feed very large, heavy and highly abrasive raw materials, such as run-of-mine ore from hoppers, especially for primary crushing applications.

Rotary Feeders can be used control the discharge rate of fine, powdered material from storage and act as an airlock in pneumatic conveying applications and to minimize cold air leakage into high-temperature systems like the raw mill inlet.

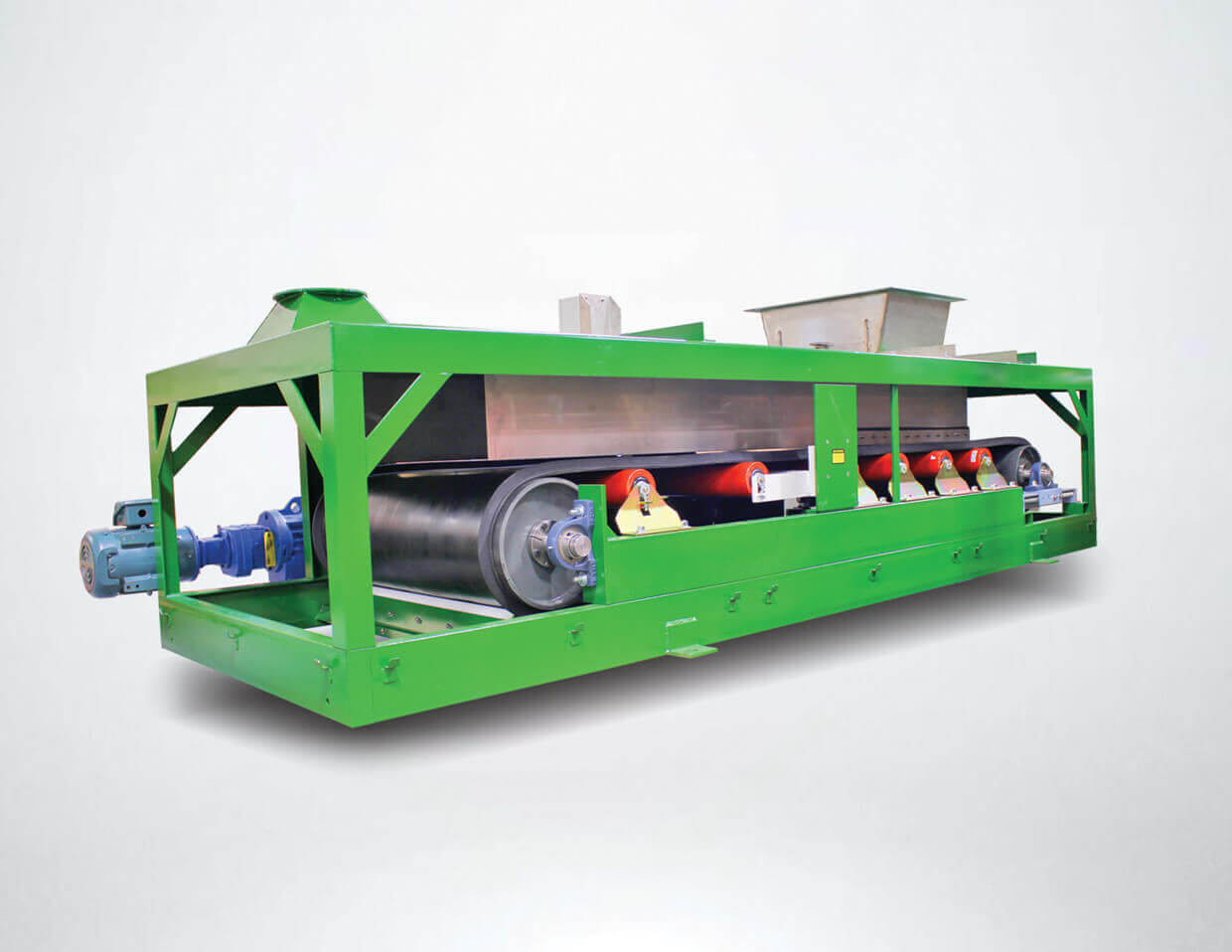

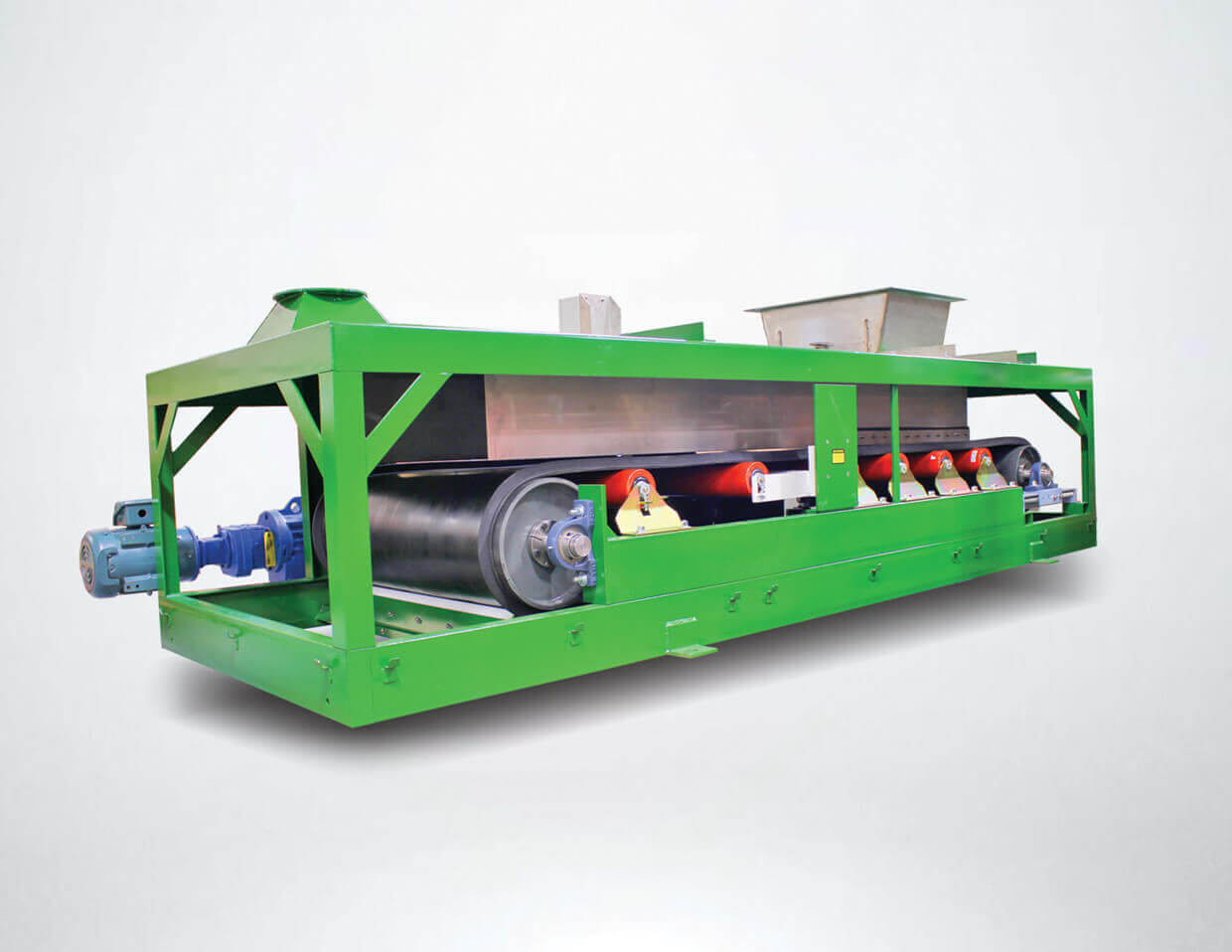

Weigh Belt Feeders

Weigh Belt Feeders (or Weigh Feeders) are ideal for a range of controlled feeding and accurate material proportioning applications. These are short, self-contained, belt conveyors that incorporate an integral belt scale and can be used to continuously monitor and control the material mass flow rate before it enters key processes (raw mill or kiln). These are critical for quality control and blend optimization. They provide high precision, are excellent for a wide range of feed rates and suitable for blended cement production.

Originally developed in the 1970s for the cement industry, Thayer Scale’s Model MD & MDL feeders are extremely rugged weigh belt feeders commonly used across many heavy industrial applications. These Weigh Belt Feeders are proven to withstand extreme environmental conditions, including abrasive dusts, corrosive fumes, wide temperature fluctuations and vibrations – without any detrimental effects to performance or accuracy. With the Model MD being able to handle flow rates between 2 – 400 STPH and the MDL being specifically designed for the lower end of that range, both styles of feeder offer a range of rugged weigh belt options ideally suited for harsh industrial environments.

The Model MD and MDL are suitable for heavy, compacted, high bulk density materials of all particle sizes. They are the ideal feeders for medium to high feed rates for both general and heavy industrial applications.

Built to Survive

Recently, Neal Systems sold a replacement Weigh Belt Feeder to replace a unit originally installed in 2008 in a harsh outdoor cement production environment. Being “Built to Survive” this equipment had been running well for nearly twenty years, providing accurate rate measurement. After many years of reliable service, the frame of the feeder was beginning to succumb to corrosion under the harsh operating conditions. The replacement unit was upgraded to a full stainless-steel frame construction, which will result in an even longer service life

The Weigh Belt Feeder, a Model MD-24-TM, is used to meter iron ore into the production process. Iron ore is added to cement to enhance its strength and accelerate the hydration process. As a fluxing agent, iron ore helps chemical reactions with calcium and aluminum during high-temperature processing, forming compounds like tricalcium aluminoferrite, which contributes to the hardness and strength of the cement.

This manufacturer uses several other Weigh Belt Feeders and Conveyor Belt Scales in their cement product process to handle materials like limestone, gypsum, clinker, petroleum, coke, slag, fly ash, all used to create a variety of construction materials.

In addition to the cement industry weighing and feeding equipment is used throughout a wide range of industries and bulk material handling applications and it is essential to have the correct equipment in place to ensure the accurate and precise flow control of material at every stage of your process.

To learn more about how Neal Systems and Thayer Scale can help with your Weighing and Feeding needs, please contact us here.

January 15, 2026 | Company NewsProduct News

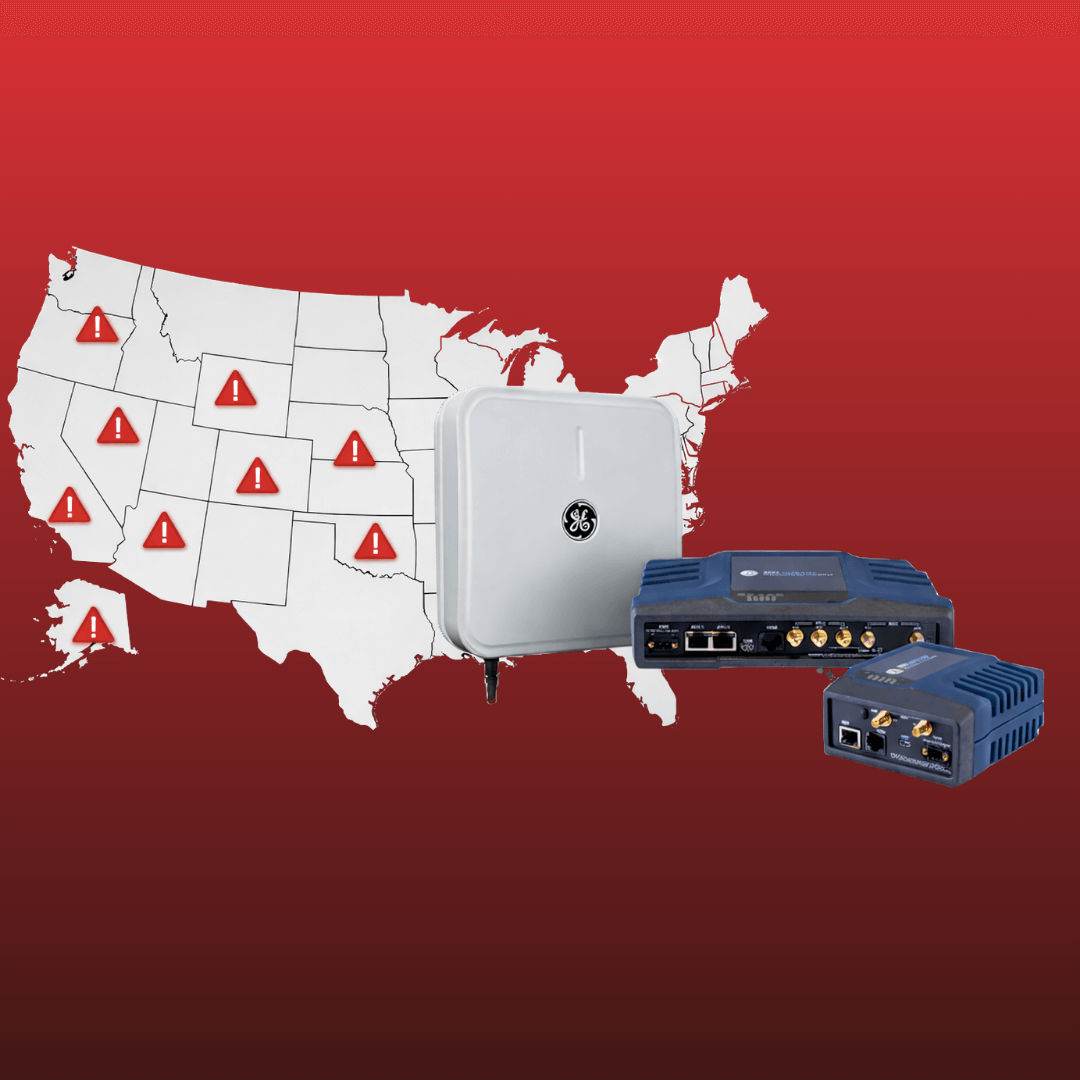

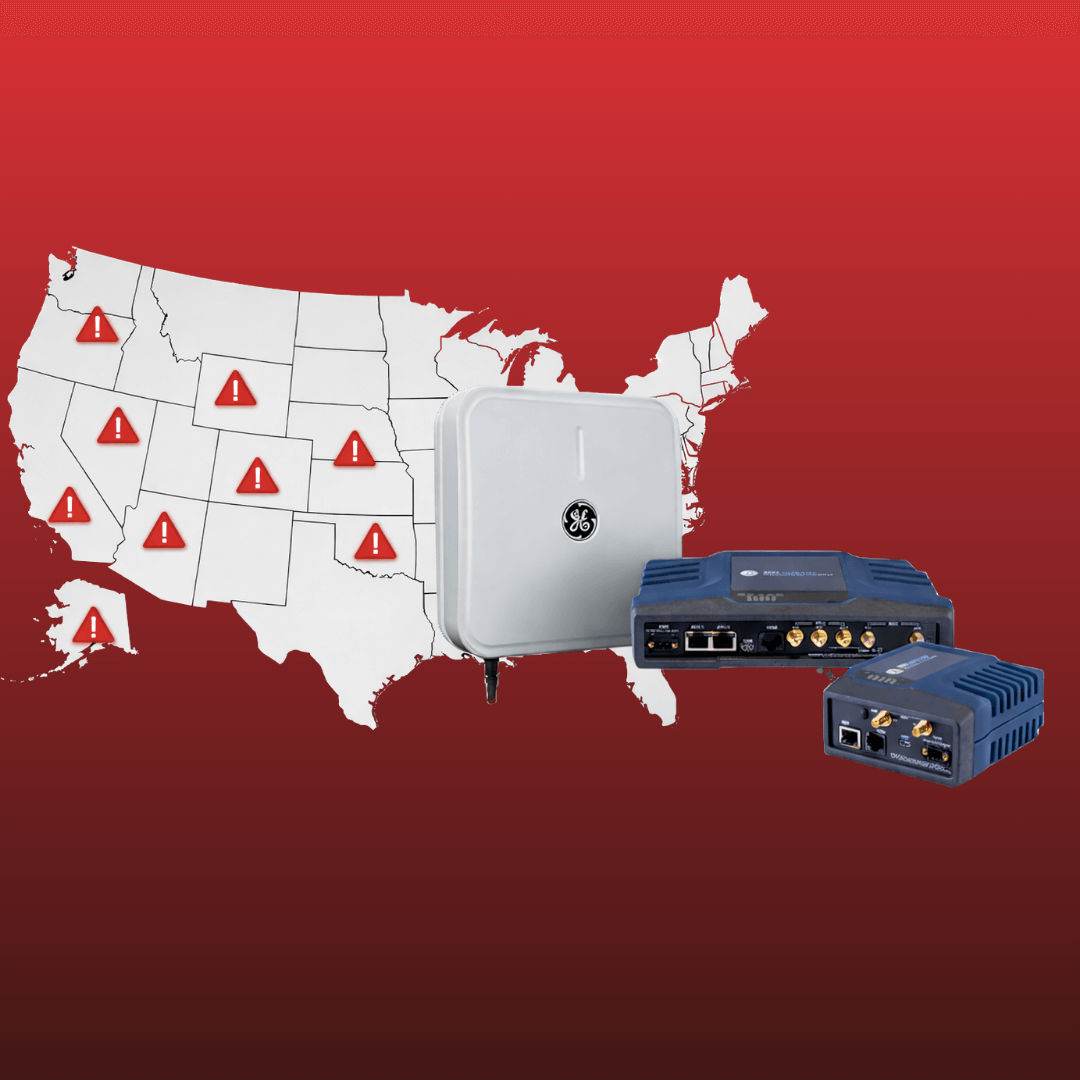

The recent Verizon cellular service disruption has affected municipalities and utilities across multiple regions. While outages are an expected reality of large communications networks, they highlight an important consideration for municipal utilities: how resilient are the communication paths supporting SCADA and remote operations?

Connectivity as a Utility Dependency

Water, wastewater, and electric utilities rely on communications networks to:

-

Monitor and control SCADA systems

-

Operate remote pumping and lift stations

-

Monitor substations and distribution assets

-

Transmit alarms and operational data

When communications are interrupted, utilities may temporarily lose visibility, control, or alarm awareness – even if the outage is brief.

The Challenge of Single-Path Communications

Many municipal systems rely primarily on a single communications method, often commercial cellular. Cellular is typically easier and more cost-effective to deploy, making it an attractive option for remote and distributed assets.

However, this approach also means that ownership and control of critical operational data and connectivity are partially offloaded to a third party. During outages, that tradeoff becomes more visible.

While cellular networks are highly reliable, they are not immune to:

-

Carrier outages

-

Fiber cuts

-

Power disruptions

-

Weather-related events

When no alternative path exists, utilities may face operational blind spots during these events.

Designing for Resilience

To reduce this risk, many utilities are moving toward hybrid communication architectures. These designs:

-

Incorporate multiple wireless technologies

-

Allow systems to fail over if one path becomes unavailable

-

Reduce dependence on a single carrier or network type

An example of this approach is the

GE Vernova MDS™ Orbit industrial communications platform, which supports cellular, licensed and unlicensed radio, and Wi-Fi within a single device. This flexibility allows utilities to design redundancy based on operational requirements rather than being limited to one network.

Why This Matters for SCADA and Operations

Resilient communications support:

-

Higher system uptime

-

Continuous alarm visibility

-

Improved operational confidence

-

Better alignment with critical infrastructure cybersecurity and reliability standards

Learning From Outages

Rather than viewing outages solely as disruptions, they can serve as stress tests for communication architectures. They help utilities identify where single points of failure exist and where additional redundancy may be warranted.

As municipal utilities continue modernizing infrastructure, communications design will remain a foundational component of system reliability – Not just during outages, but every day.

Take a moment to assess your utility communications: where are the single points of failure, and how would your systems respond during an outage?

September 3, 2025 | Product News

Struggling With Long Lead Times on Temperature Controllers?

If you’ve been sourcing Automation Direct SOLO SLM Single Loop Modular Temperature Controllers, you may have noticed the issue: lead times have stretched dramatically, with some customers currently backordered into November. These systems typically consist of one to seven single-loop modules with one input and two outputs, with optional ramp and soak profiling.

The good news? Watlow offers several alternatives that are available in days—not months.

Watlow Competitive Options

-

EZ-ZONE® RM – Ships in 3–5 days.

-

Modular controller with 1–4 loops per module (up to 8 loops and 16 outputs when two modules are combined).

-

On-board Modbus® RTU available.

-

Flexible and scalable: configure from 1 to 152 control loops and up to 256 monitor points by mixing and matching modules.

-

Integrates on-off or PID control, monitoring, limit control, and communication modules.

-

EPC2000 – A powerful back-of-panel option with fast availability.

-

PM LEGACY & PM PLUS – Ideal for one or two loops of control, both shipping in as little as 3 days.

Why Choose Watlow?

Watlow’s modular, scalable platforms ensure you can design exactly what you need—without being held up by extended supply chain delays. Whether you require a few loops or a large-scale system, Watlow solutions are built for flexibility, speed, and long-term reliability.

Proposed Replacements for SOLO SLM:

-

EZ-ZONE® RM

-

EPC2000

-

PM LEGACY

-

PM PLUS

Neal Systems is a proud Watlow representative with decades of experience helping customers design, specify, and support temperature control systems. If you’re facing backorders or simply want the best-fit solution for your application, our team can help you get the right product fast.

June 23, 2025 | Company NewsProduct News

We’re thrilled to announce a major expansion: Neal Systems is now the official representative for Foxboro Instrumentation and Remote Operations throughout the entire state of New York.

This includes solutions in:

-

Instrumentation – Flow, Pressure, Level, and Temperature

-

Remote Operations – GeoSCADA (formerly ClearSCADA), SCADAPack RTUs, and Trio Wireless

Why Foxboro Chose Neal Systems

Foxboro selected Neal Systems as their trusted partner for New York based on several key strengths:

-

Proven Track Record – Over 15 years representing Foxboro in territories from Pennsylvania to Virginia.

-

Established NY Presence – A 20+ year history supporting New York customers with brands like Metrix, MTL, L&J, Alta Solutions, Keller, Watlow, Eurotherm, and Chessell.

-

Deep Technical Expertise – From instrumentation to automation, our engineering bench runs deep.

-

Customer-Focused Support – A team built around fast response times, hands-on help, and personalized training.

-

People & Logistics That Make a Difference – Our culture and commitment to excellence set us apart.

Meet Your Neal Systems Support Team

We’ve assembled a team of experts to make sure New York customers have everything they need—from technical guidance to fast service and support.

👥 Customer Service

Our customer care team is always ready to assist with orders, questions, or anything in between.

-

Customer Care / Order Entry – Jacklyn Tully

-

Operations Manager – Laura Kane

-

Customer Experience Manager – Helen Batchelor

🌍 Outside Sales

Serving every corner of New York:

-

Western NY – Justin Bendik (Territory Manager)

Based locally and available to support the Buffalo region and beyond. (We’re also hiring for a rep in Buffalo—come chat with us if you’re interested!)

-

Eastern NY – Ed Owens (Territory Manager)

-

Sales Manager – Mark Pfender

🧠 Application Engineering

Whether it’s instrumentation or remote operations, our engineers love a challenge:

-

Instrumentation – Walter Freeman

-

Remote Operations – Dave Schroeder & Joe Klinkhoff

-

General Support – Hugh Davison & Shane Filer

🛠️ Field Service

Our field service team provides on-site help, calibration, commissioning, and more:

-

Cecilio Ramirez

-

Joe McCracken

-

Brian Weischedel

🔧 Technical Support

Ready to troubleshoot and assist with any setup or application questions:

-

Hanlon Doyle

-

Dexter Vilar

Want to put a face to the name? Visit our Team Page to get to know us better.

We’re proud to bring the trusted performance of Foxboro instrumentation—and the reliability of Neal Systems support—to even more customers across New York.

Need a quote, want to discuss your next project, or just have a few questions? Contact us here.

View Official Announcement Letter

April 3, 2025 | Company NewsProduct News

Dear Customers,

Additional tariffs have come into effect as of 00:01 on 3rd April 2025 and will be seen as an additional line item per product on invoices. Our expectation is that these will range from 0% to 25% based on the origin of manufacture (UK 10%; EU 20%; Mexico & Canada 0% OR 25% dependent on exemptions; US 0%). We are offering three options to accommodate this:

- Contact here for additional information, noting that in the short term we may not have much additional information.

- Cancel your purchase order

- Accept the additional tariffs

If we do not hear back from you within 5 days of the order acknowledgement we will assume that you are accepting the tariffs and we will proceed with shipment. We recognize how frustrating this is for you and are working as diligently as possible to determine the impact on each and every order but please be aware that we do not have a full picture at this time. Note that Neal Systems will only make tariff charges when they have been placed on the goods by the government and will not mark them up in any way.

Estimated Tariffs Per Product

Eurotherm products – 20%

Draeger products – 20%

Metrix products – 0%

MTL products – 10%, 20% or 26%

Foxboro Products – upto 25%

GE Orbit radios – 0%

Cattron product – 0%

M-System products – 20%

PR Electronic products – 20%

Servomex products – 20%

Keller products – 20%

Elpro products – 10%

Expo products – 10%

Alta products – 0%

Automation service products – 0%

Minco – Minco manufactures all products in the USA and maintains an almost exclusively USA based supply chain. As such, Minco expects a minimal impact to product pricing due to tariffs

As of 4-3-25 this information is our best understanding of the situation. Note that this is NOT a definitive statement but is meant for guidance only. There are many unknowns that we are trying to resolve and will be updating this page regularly. Actual tariffs charged may differ from what is shown here.