Eurotherm Highlights Products that Meet NADCAP’s AMS2750E Requirements for Furnace Thermal Uniformity Testing

September 23, 2015Eurotherm provides a range of products that meet the accuracy, data collection, storage, and reporting requirements of the new standard:

The 6100A TUS Recorder offers unrivalled input accuracy with a 125ms total sample rate for up to 15, high accuracy, universal temperature inputs. The 6100A TUS Recorder easily meets the requirements of AMS2750E (Table 3 Specification – Field Test Instrument +/-1ºF) – with instant on accuracy, an overall max error of +/-0.5ºF, and high stability to minimize drift; this is a best in class device designed for the Heat Treating Industry. The portability of the TUS recorder makes it extremely versatile and, with 15 thermocouple inputs, is suitable for any small or medium sized furnace.

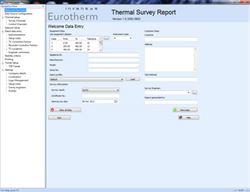

Temperature Uniformity Survey reports are a mandatory part of AMS2750E pyrometry compliance, and the report content and format are well defined in the specification. With the advent of digital recorders, it is possible to take the output from the survey recorder and automate the production of the report. This adds a desirable level of efficiency to the whole process of thermal process equipment accreditation. This new package automates the production of survey reporting by combining the secure .uhh file data from a Field Test Instrument with the database management of Eurotherm Review. This directly produces reports that comply with the requirements of AMS2750E.

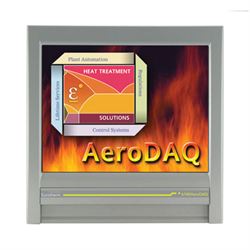

Using a furnace when it has exceeded the allowable period for calibration, TUS (Thermal Uniformity Survey), or SAT (System Accuracy Test) can result in audit noncompliance, and monetary loss. AMS2750E is forcing aerospace suppliers to adopt rigorous procedures for furnace maintenance. The AeroDAQ is designed to help you comply with Aerospace industry standards. The 6180 AeroDAQ provides thermocouple life monitoring functionality based on AMS2750E, Sections 3.1.5 and 3.1.5.3. Both thermocouple Uses and Days remaining are accounted for to help assure that thermocouples are not used beyond their maximum life as per AMS2750E.

A data recorder with PID control, the nanodac recording functionality uses the secure strategies and UHH format developed by Eurotherm through years of recording expertise. As well as multiple real-time views and historical review on the product, multiple data archiving strategies are provided using the 50MB onboard Flash memory, removable USB, and data transfer via FTP to a specified server. Heat Treatment is one of the many processes that often needs to vary the set point of the control process over a set period of time; this is achieved by using a set-point program. The nanodac offers an optional Dual Programmer option supporting up to 100 programs locally, each program supporting 25 segments. The nanodac also provides remote access to a further 100 programs that can be easily retrieved via FTP and 100 programs using the USB memory stick.

The 3508 and 3504 offer much more than temperature control – advanced features and options make them capable of small machine control. They provide flexible I/O options to control and measure a multitude of processes – temperature, potential, humidity, flow, pressure, level, viscosity, additive dosing, and many more. Specialist function blocks, recipe selection, setpoint programmers, maths, logic, timer functions, and flexible communication options are just a few examples of what makes these instruments a key part of a total process solution.

These data loggers offer the built-in protection and traceability you need. Your most valuable asset is the data collected for process and legislation purposes. Protection includes Audit Trail for 21CFR Part 11 and Nadcap applications, with recorded login, use of unique usernames and passwords. The 6180A offers unrivalled input accuracy with a 125ms total sample rate for up to 48 input channels. Input channels are freely configurable to suit your process requirements. Each instrument has an intuitive, touch screen display to enable operators to clearly view process data in varying formats. All have onboard Flash data storage capability, Ethernet communication, and choice of Compact Flash or SD Card. Data is stored in a tamper resistant binary format that can be used for secure, long term records of your process.

Click on more information to learn more.