How are you managing your rotating and reciprocating machines?

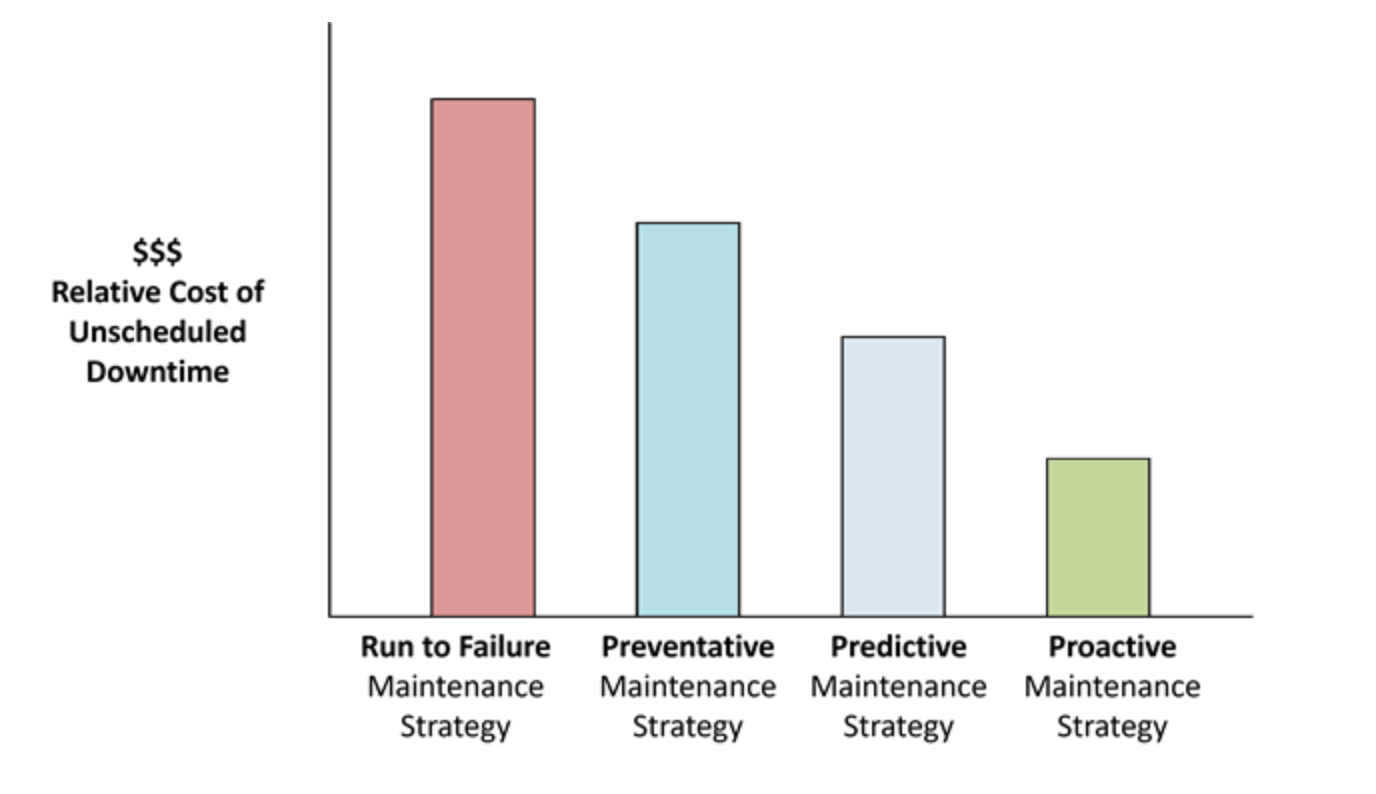

April 18, 2022Run to Failure (worst) – most expensive way to operate. Run the machine until it fails then replace it.

Preventative Maintenance (good) – repairs to the machines are made on a periodic basis, regardless of the machines condition. Oftentimes, the preventative repairs are more damaging to the machine than if the machine was left alone – this is the next most expensive way to operate.

Predictive Maintenance (better) – repairs to the machines are made based on the condition of the machine, based on predictive technologies like vibration monitoring, thermal imaging and lubrication analysis – this is one of the least costly ways to operate, but needs a consistent investment in permanent monitoring via transmitters integrated with the existing Control System (PLC’s, SCADA, RTU’s, etc.).

Proactive Maintenance (best) – repairs to the machine are made based on the condition of the machine, based on predictive technologies like thermal imaging, lubrication analysis, combined with continuous vibration monitoring with data correlation with the plant process parameters of pressure, flow, power level, capacity, etc. – this is the least costly way to operate, but has the highest initial startup cost.

Find out how NSI’s team of expert engineers can provide the best vibration monitoring solution for your plant! Contact us here!