Blog

February 20, 2015 | Product News

The GECMA RT is MTL’s new generation HMI series for safe operation in hazardous areas to reduce cost, maximize productivity, and increase plant safety.

The new GECMA RT is suitable for the strictest of hygienic conditions, aggressive production environments, and hazardous areas such as often found in the pharmaceutical, chemical, petrochemical, oil & gas and off-shore manufacturing industries. This future proof solution has been designed with state of the art technology and unique features to bring the best value:

- Unique and innovative platform concept. modular design saves time and cost during installation, commissioning; and operation

- Individually certified modules for quick and easy on-site maintenance

- 19″, 22″ Full HD and 24″ Full HD displays with LED backlight technology for optimum quality and viewing

- Lightweight, Slimline design helps to optimize space and offers flexibility of application

- Fiber optic or copper data transmission for cost effective, reliable, and increased volume of data transfer

- Unique Intrinsically Safe connection and Alarm visualization to ensure safe, continuous operation in the hazardous area

- Single line data transmission for simple, cost-effective installation and reliable transmission

DVI & USB interfaces/transparent USB for quick and flexible connectivity

February 20, 2015 | Product News

The MTL4850 HART Multiplexer offers a smaller footprint solution ideally suited to both retrofit and new project applications. Termination boards, carriers, and integrated backplanes are available to enable the MTL4850 to interface to various instrumentation applications.

The MTL4850 Multiplexer offers the following benefits:

- Channel to channel isolation

- Isolated power supply

- Auto baud-rate detection

- LED indication for fault diagnosis

- Supports HART Rev. 5-7 devices

- SIL3 certified for connection to safety loop

- Onboard event log

- ATEX, FM and CSA certification

The MTL4850 Hart Multiplexer is now Safety Integrity Level (SIL) 3 rated for connection to instrument loops performing safety functions up to and including SIL3. The international standard IEC 61508:2010 provides guidelines to achieving an adequate SIL for systems, sub-systems, and components. Functional Safety Management requirements are found in IEC61508, which states that suppliers and subcontractors shall demonstrate functional safety management.

MTL conforms to the requirements of the international standard IEC 61508:2010 for functional safety by being certified as a Functional Safety Management company.

February 20, 2015 | Product News

For a complete evaluation of your facility’s SCADA system, Neal Systems is pleased to offer Woodard & Curran’s SCADACheck service. SCADACheck is a full evaluation that includes assessment, planning, and budgeting for smart capital and operational decisions. SCADACheck can be scaled for both large and small operations to help save you time, reduce costs, and increase efficiency with these major benefits:

Implement Better Technology to Reduce Costs

The assessment will focus on solutions that make sense for your operation, merge with your strategic goals, and identify opportunities to reduce operational costs.

Smart Capital Planning

Woodard & Curran can provide guidance on capital needs based on the age of your equipment and the complexity of your system. Their recommendations have helped many clients justify their capital expenditure plans.

Use Their Experienced Team

Their extensive electrical, instrumentation, information systems, and control services expertise encompasses engineering and implementation services for water, wastewater, and industrial facilities.

Click here for more information.

January 7, 2015 | Product News

Red Lion Controls, the global experts in communication, monitoring and control for industrial automation and networking, today announced that its newest plug-in modules for the popular Graphite™ series of advanced human machine interface (HMI) panels were named “Best Product of 2014” by Control Engineering China. Additionally, Red Lion was recently selected as a 2014 “Wind Industry Leader” by the readers of Windpower Engineering magazine, a leading North American publication on engineering, design and maintenance of wind power equipment. See the rest of the story here.

October 31, 2014 | Product News

Quick Product Overview:

Custom Thermal Uniformity Survey (TUS) solution uses thermocouple panels (thermocouple jacks and T2550 series) and a hardened laptop running a custom Wonderware interface for generating TUS reports. A special feature is that it is able to “learn” a furnace’s unique survey requirements, including number of thermocouples, thermocouple types, temperature ranges, etc.

Engineering / Design Company:

Neal Systems Inc (NSI), one of the largest US-based Eurotherm distributors and system integrators

Background:

Approximately five years ago, Eurotherm USA generated an “AUTOMATIC TUS REPORT” marketing mailer to all US-based companies that were registered as being NADCAP-certified. A local steel company responded with interest, and NSI was able to sell them a Chessell 6180 with the TUS software.

They quickly realized that the solution wouldn’t work for their operators, as they have over 130 furnaces which vary widely in both Celsius / Fahrenheit as well as number and type of thermocouples. As they were having to do close to 500 reports per year, the concept of having each operator change the degrees type, # of channels, and thermocouple type for each report was going to create a huge potential for errors.

Design Concept:

Design Concept:

NSI gathered information on the number of furnaces, the number and type of thermocouples for each furnace, and the report type expected with each furnace. A design concept was created where a Wonderware-based interface would effectively be able to “learn” each furnace such that the operator’s only responsibility would be to tell it the furnace name. Two thermocouple panels were designed (one is pictured left) which would account for every possible combination of thermocouple types that the operator might need for the specific furnace test (occasionally two panels would have to be connected together).

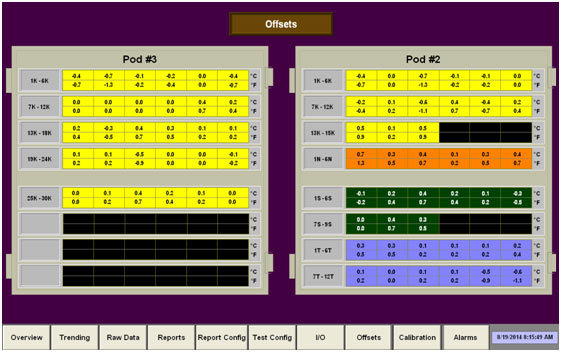

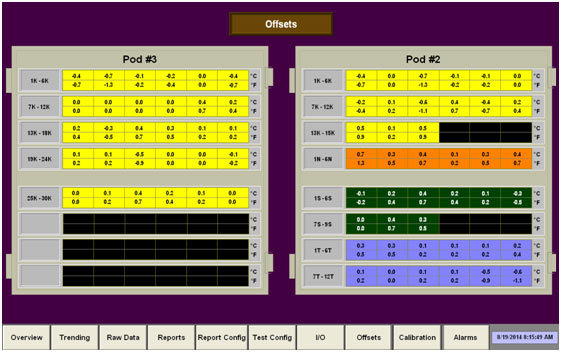

Once the correct furnace was chosen in the Wonderware screen, the system would automatically look to see if the correct number of thermocouples was plugged into the two main thermocouple panels (called “pods” by the customer). Below is pictured an example where the user was viewing “Pod #2”.

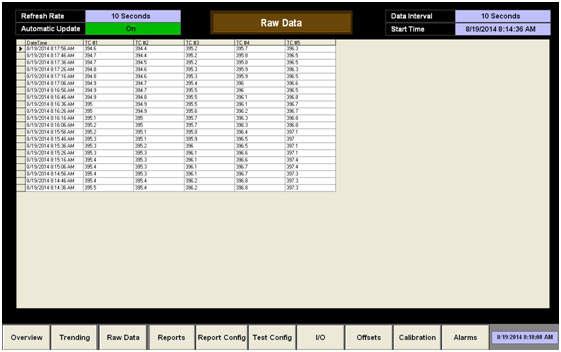

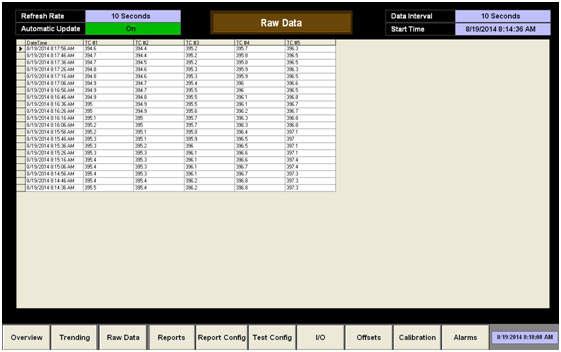

Once the survey was completed, the operators would have an opportunity to review the raw data, as seen below:

Assuming the survey was a good one, the operator could then press a button, which would generate a full report that was designed either for compliance to their end customer’s requirements, or for a NADCAP auditor (or both in some cases).

The system has been used now for a few years by the customer in their 130+ plus furnaces, and we have recently designed another iteration for them that includes new report changes that better comply with some of the AMS2750E changes.

Contact Information:

Neal Systems Inc (NSI)

Shane Filer

122 Terry Drive

Newtown, PA 18490 (USA)

215-968-7577

Design Concept:

Design Concept: