April 3, 2023 | Company News

Temperature control is critical for the pharmaceutical industry. Proper temperature control ensures safety, efficacy, and quality. There are a variety of temperature requirements for pharmaceutical products depending on the product type and storage conditions. The US FDA regulates the temperature control requirements in the pharmaceutical industry through the Code of Federal Regulations (CFR). Neal Systems has extensive experience with ensuring our customers are able to adequately follow sections 211.42.3.10 and 211.142 of the CFR.

CFR Section 211.42.3.10 outlines the temperature and humidity control requirements for drug product storage areas. Drug product storage areas must be designed to maintain proper temperature and humidity levels suitable for the products being stored. These temperatures and humidity levels must be monitored, recorded, and controlled. Any data outliers need to be investigated. This section also requires a written record, that can be made available to the FDA, of temperature and humidity monitoring, to include the date, time, temperature, and humidity readings.

CFR Section 211.142 outlines the temperature control requirements for drug products during manufacturing, processing, and packaging. Drug products must be manufactured, processed, and packaged under appropriate temperature and humidity conditions. This section also states that any equipment used in the manufacturing, processing, or packaging of drug products must be capable of controlling the temperature and humidity levels required for the products.

How can Neal Systems help?

Neal Systems can ensure your equipment is calibrated and maintained to ensure humidity and temperature are controlled within the appropriate ranges. We provide monitoring and recording instrumentation that allow for accurate record keeping, as well as monitoring to alert to any temperature or humidity outliers that may require investigation. Our recording instrumentation can provide both an audit trail of any changes (to ensure compliance) as well as 21 CFR 11 electronic signatures.

Our team works one-on-one with our customers to find their specific needs and recommends the best product and solution for their unique situations.

Are you looking for an easier and more efficient way to ensure you are within regulatory requirements? Our team of engineers and service technicians are here to answer your questions.

March 29, 2023 | Company News

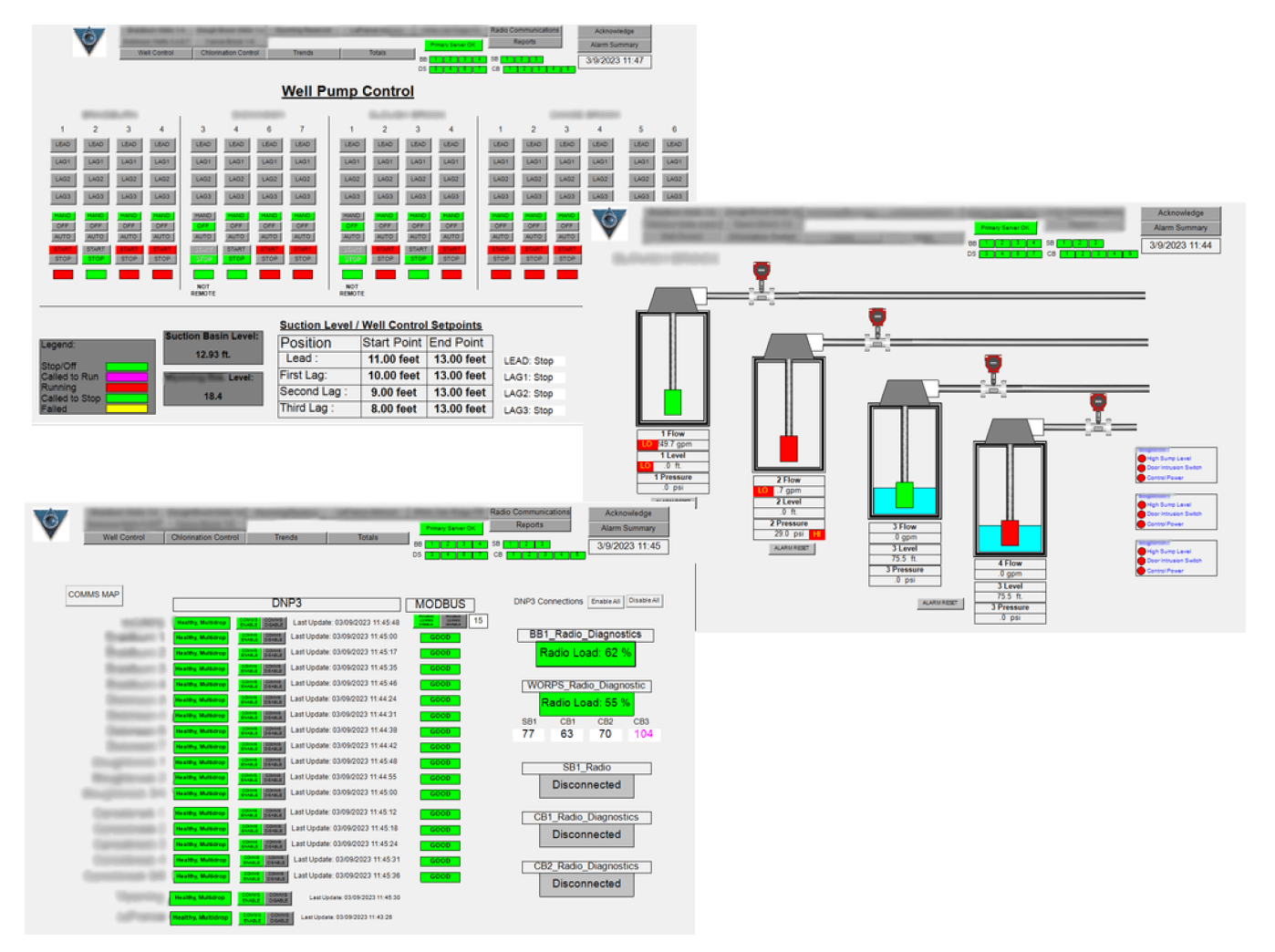

Water contamination has been recently been making headlines due to a variety of unforeseen incidents. It is becoming increasingly important to take preventive measures to ensure that such incidents are minimized or avoided altogether. At NSI, we understand the critical role that regular maintenance and monitoring of a plant’s effluent play in minimizing or avoiding these potentially catastrophic situations.

Neal System’s offers a comprehensive range of instrumentation and analyzers that are essential for efficient plant management and monitoring. Our team of experts provide installation, troubleshooting, calibration, and maintenance services for the following:

- Pressure

- Flow

- Temperature

- pH

- Dissolved Oxygen

- Chlorine/Chemical Feed

- Gas leak detection (chlorine, hydrocarbons, ammonia, carbon monoxide, hydrogen sulfide, and oxygen)

- Qualities of Water: TOC, COD, BOD, TNb

Our team is proud to say that our engineering and service teams collectively have more than 200 years of experience in water and wastewater management. We’re committed to providing the highest quality solutions that minimize the impact of any potential leaks and to help prevent them from occurring in the first place.